We apologize for the inconvenience...

To ensure we keep this website safe, please can you confirm you are a human by ticking the box below.

If you are unable to complete the above request please contact us using the below link, providing a screenshot of your experience.

https://ioppublishing.org/contacts/

Today in Energy

- Recent articles

- liquid fuels

- natural gas

- electricity

- oil/petroleum

- production/supply

- consumption/demand

- exports/imports

- international

- forecasts/projections

- steo (short-term energy outlook)

Utility-scale batteries and pumped storage return about 80% of the electricity they store

Electric energy storage is becoming more important to the energy industry as the share of intermittent generating technologies, such as wind and solar, in the electricity mix increases. Electric energy storage helps to meet fluctuating demand, which is why it is often paired with intermittent sources. Storage technologies include batteries and pumped-storage hydropower , which capture energy and store it for later use. Storage metrics can help us understand the value of the technology. Round-trip efficiency is the percentage of electricity put into storage that is later retrieved. The higher the round-trip efficiency, the less energy is lost in the storage process. According to data from the U.S. Energy Information Administration (EIA), in 2019, the U.S. utility-scale battery fleet operated with an average monthly round-trip efficiency of 82%, and pumped-storage facilities operated with an average monthly round-trip efficiency of 79%.

EIA’s Power Plant Operations Report provides data on utility-scale energy storage, including the monthly electricity consumption and gross electric generation of energy storage assets, which can be used to calculate round-trip efficiency. The metrics reviewed here use the finalized data from the Power Plant Operations Report for 2019—the most recent year for which a full set of storage data is available.

Pumped-storage facilities are the largest energy storage resource in the United States. The facilities collectively account for 21.9 gigawatts (GW) of capacity and for 92% of the country’s total energy storage capacity as of November 2020.

In recent years, utility-scale battery capacity has grown rapidly as battery costs have decreased. As batteries have been increasingly paired with renewables , they have become the second-largest source of electricity storage. As of November 20, 2020, utility-scale battery capacity had 1.4 GW of operational capacity. Another 4.0 GW of battery capacity is scheduled to come online in 2021, according to EIA’s Preliminary Electric Generator Inventory .

Although battery storage has slightly higher round-trip efficiency than pumped storage, pumped-storage facilities typically operate at utilization factors that are currently twice as high as batteries. Increasing durations among battery applications could shift battery operations toward services that reward longer output periods. For example, in 2015, the weighted average battery duration was a little more than 46 minutes, but by 2019, weighted average battery durations had doubled to 1.5 hours. The role of batteries and their capability to provide high levels of round-trip efficiency may become more important as batteries continue to be deployed and as the intermittent renewables share of the electricity mix grows.

Tags: storage , electricity

The Precourt Institute for Energy is part of the Stanford Doerr School of Sustainability .

Mix of mechanical and thermal energy storage seen as best bet to enable more wind and solar power

To enable a high penetration of renewable energy, storing electricity through pumped hydropower is most efficient but controversial, according to the twelfth U.S. secretary of energy and Nobel laureate in physics, Steven Chu .

A combination of new mechanical and thermal technologies could provide us with enough energy storage to enable deep renewable adoption.

Chu’s analysis came as part of Stanford University’s Global Energy Dialogues series. His June 23 talk focused on the methods and costs of storing excess solar and wind power for when the sun sets and winds die down. Chu also addressed lessons learned from his time at the U.S. Department of Energy, where he oversaw unprecedented investments in clean energy via the 2009 American Recovery & Reinvestment Act. Here Chu stressed the need to hire good people, analyze real data and fight bureaucracy.

It turns out the most efficient energy storage mechanism is to convert electrical energy to mechanical potential energy, for example by pumping water up a hill, said Chu.

When the electricity is needed, the raised water is released through turbines that generate electricity. The 100-year-old technology dominates the global energy storage landscape today, with dozens of new installations under construction in China. Recent cost estimates show it to be competitive with any other utility-scale storage.

“The problem with (pumped) hydro is that it takes a long time to get permitting” in many countries, said Chu, noting that some environmentalists are “very much against hydro storage.” Nevertheless, there is a growing realization that increasing pumped-hydro storage substantially will be necessary if we are to increase wind and solar power beyond 50 percent of generated electricity.

One audience member asked if small, modular pumped-hydro systems could be a good option. Chu responded: “I am a big fan of small, modular anything.” Built in factories and shipped around the world, he explained, modular units may be easier to approve than the big, “one-off” facilities we have today.

Newer energy storage methods

As we get more energy from renewables, our need for energy storage grows, said Chu, who is a professor in Stanford's Department of Physics and in the Department of Molecular and Cellular Physiology in its School of Medicine. Once we get to 50 percent renewable energy, we need far more storage than we have. The total electricity consumption in the United States in 2018 – 2019 was about 4,000 terawatt-hours (TWh) of energy with a generating capacity of about 1,200 GW. The United States currently has only 31 GW of stored energy power—only 2.5 percent of our current generating capacity. At 80 percent penetration of renewables such as wind and solar energy, it is estimated we would need four days of storage energy (100 hours) at our full generation capacity to minimize energy curtailment (the throttling back of renewable generation), Chu explained. Most regional U.S. grids could survive on large-scale electricity storage systems for a few minutes today.

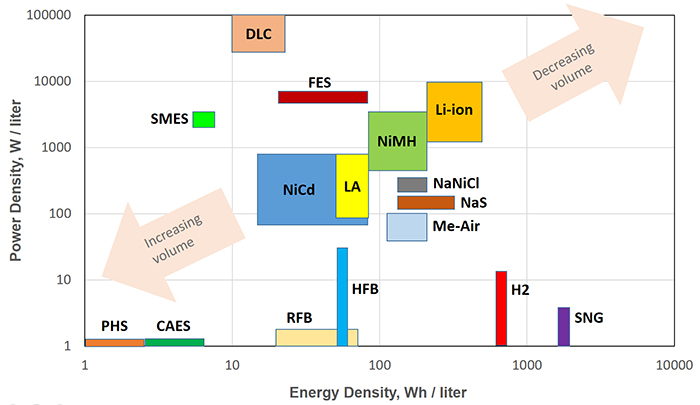

The current full cost of lithium-ion battery storage is about $300/kWh, which is at least a tenfold higher cost than for even 12 hours of pumped-hydro storage. How can we reach the storage capacity we need in a way that is more cost-effective than lithium-ion batteries?

As an alternative to new dams, researchers are developing innovative mechanical storage technologies, Chu explained. This includes pumped storage by displacing water with air using isothermal compression and expansion in canisters one to two kilometers deep on the seafloor. Compressed air energy storage technologies using hollowed-out salt caverns with isothermal energy transfer also are being seriously considered.

“But, what about using electricity just to heat something up?” asked Chu. Within 10 to 20 years, wind and solar energy at the best sites in the world is expected to be as low as $15 /MWh (1.5 ¢/kWh) or equivalently $4.40/ MM Btu. Chu converted to MM Btu (million Btu) since this is the unit of energy used to price natural gas. At $4.40/ MM Btu, renewable energy will be less than the cost of natural gas in many regions of the world. Converting electrical energy directly into heat with resistive heating is thermodynamically inefficient since it creates excessive entropy. However, mechanical engineers and physicists alike have realized that there may be very efficient methods of using adiabatic compressors and expanders—such as Brayton turbines—to create a method of storing and extracting heat energy mechanically. Thus, heat storage begins to look like pumped-hydro storage, and for this reason the new technology has been dubbed a Brayton battery.

Brayton turbines are used in two ways to generate electricity. Natural gas turbines compress air, burn the fuel in a combustion chamber and extract mechanical work in the gas expansion stage. Alternatively, water heated to high pressures and temperatures well above the supercritical point, where there is no longer a distinction between liquid and vapor water, is used as an energy transfer fluid. After extracting work in the expansion stage, the cooled, low-temperature steam is returned to a high-temperature, high-pressure state through two stages of recompression. Energy “recuperators” are used the bring the steam to higher temperatures before adding fossil fuel heat. In this way the average temperature where the heat energy is added more closely approaches the idealized Carnot engine where the theoretical maximum thermal efficiency is η= (T hot – T cold) /T cold , where T hot is the temperature of a high-temperature reservoir and T cold is the temperature where the waste heat is expelled.

In the past decade, engineers have begun to pilot the use of supercritical CO 2 as the working turbine fluid. A new turbine designed to burn a mixture of natural gas and oxygen in which 94 percent of the mass of the fluid is high-pressure supercritical CO 2 (The Allam Cycle) is being piloted in joint venture with a start-up company, NetPower, and Toshiba.

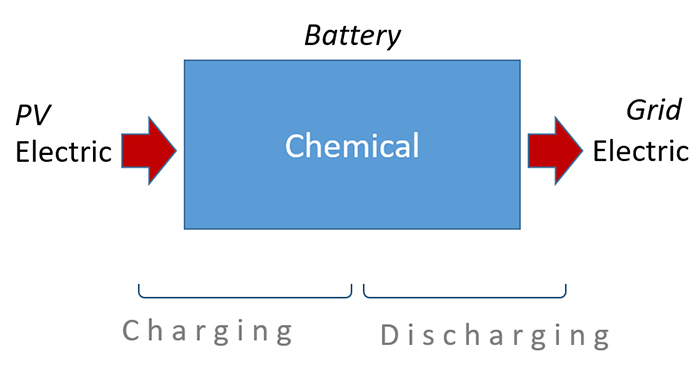

Note that the conversion between electrical power and mechanical power is up to 98 to 99 percent energy efficient. Because of this high-conversion efficiency, the round-trip efficiency of pumped-hydro storage is 75 to 85 percent energy efficient, despite all of the friction and turbulence generated in moving water. Similarly, an efficient Brayton turbine can be used to pump heat between thermal reservoirs. In a case using two cold and two hot thermal storage reservoirs, an estimated 75 percent efficiency may be achievable. In the new thermal storage schemes, energy recuperation also is essential to maximize the overall efficiency when heat is stored in the high-temperature reservoir in the charging mode and extracted in the discharging mode of the Brayton battery. While utility-scale thermal storage is still unproven, a number of companies are trying to commercialize these ideas.

Another way to store excess, inexpensive renewable electricity is to generate supplies of energy-rich chemicals. The first widely deployed technology is likely to be the generation of hydrogen via the electrolysis of water. While the production of hydrogen and oxygen by electrochemically splitting water has been known since the beginning of the eighteenth century, there is renewed interest in improving the overall energy efficiency and H 2 production rate to be competitive with commercial hydrogen production. Virtually all hydrogen is produced from steam methane reforming (SMR), a process that extracts hydrogen from natural gas and releases carbon dioxide. While converting hydrogen into energy, either through combustion or through fuel cells, has no carbon emissions, “the full life cycle (of SMR-produced hydrogen) is not clean at all,” Chu explained. In the SMR process, seven kg CO 2 are produced to produce one kg of H 2 while burning diesel fuel releases 3.15 kg of CO 2 /kg of fuel. Even after accounting for the improved efficiency of a hydrogen fuel cell, a H 2 powered truck only reduces the CO 2 by 40 percent when compared to a conventional diesel heavy-duty truck. Similarly, burning natural gas produces about 0.55 kg of CO 2 /kWh of energy as compared to 0.21 kg of CO 2 /kWh in burning a kilogram of SMR-produced hydrogen.

Producing hydrogen from water using solar power reduces the CO 2 emissions to nearly zero. Better still, if hydrogen is produced from biomass that captures CO 2 from the atmosphere and the excess CO 2 is sequestered, the fuel can produce negative emissions of up to 20 kg of CO 2 per kg of H 2 used for energy.

The widespread use of hydrogen will require a new pipeline distribution system, according to Chu, noting that U.S. infrastructure lacks the ability to transport hydrogen. Repurposing natural gas pipelines is not feasible, Chu said, because of hydrogen embrittlement that will cause the steel pipes to crack under the stress of the high-pressure pipelines. Building new hydrogen pipelines with fiber-reinforced polymer materials could be as inexpensive as steel piping when deployed at scale. Also, using the existing natural gas right-of-way would help reduce costs of the hydrogen infrastructure.

Another active area of science and technology development is the development of a new class of utility-scale electrochemical storage based on chemical flow batteries. For example, a novel sulfur-lithium or sulfur-sodium flow battery is being developed where the cost of the chemical materials is tenfold and one-hundred-fold lower when compared to the dominant vanadium redox flow battery used today. Just as wide-scale deployment of electric vehicles will demand a shift to lower-cost materials than cobalt, nickel and manganese, massive deployment of flow batteries cannot use vanadium. Sulfur is the most attractive material for both EV batteries and stationary utility batteries.

Lessons learned at DOE

As the U.S. secretary of energy, Chu was tasked with implementing a large part of the 2009 American Recovery & Reinvestment Act. Created to stimulate an economic recovery in response to the Great Recession, it included $35 billion for investments in clean energy and lower-carbon-polluting vehicles.

Asked to reflect on lessons learned while in federal government, Chu said, “You’ve got to get really good people and you've got to always fight the bureaucracy growth.” Federal programs create so much paperwork and come with so many reporting requirements that many companies think twice about participating in otherwise beneficial programs.

Successful Recovery Act programs included the initiation of ARPA-E and investments in the U.S. electrical transmission and distribution system. The co-investment on synchrophasor technology and the linking of these power measurement units are essential in building a more robust transmission and distribution system, especially as we use more wind and solar energy. The Recovery Act fund investments in renewable energy and advanced automobile technologies through its loan guarantee program were also successful. Although the DOE was heavily criticized for the failed loans of Solyndra and Fisker, it saved Tesla and Ford from certain bankruptcy while stimulating the development of greener vehicles. Additionally, the first five large solar farms with over 100 MW of generating capacity were financed at a time when Wall Street considered these projects as too risky to touch.

The loan program was an effective method of taking innovation from initial demonstration of technology to large-scale deployment by greatly leveraging debt and equity investments in the private sector. Out of the nearly $30 billion of disbursed loans, the actual and estimated losses as of March 2020 are only 2.74 percent of the invested government money. The downside of the loan program was that it demanded the loan recipient be under detailed government scrutiny, and the bureaucratic compliance added significant costs and discomfort. “It’s as if you have a government colonoscopy without anesthesia” for the life of the loan, Chu said.

Having hard data is also important to measure the success of government programs, according to Chu. The DOE weatherization program could have been more successful if it had established a baseline so it could monitor the program’s effect on energy bills and thermostat readings before weatherization and measure the money saved and comfort gained after the work was done. Instead advocates and critics ended up arguing over the estimates of the cost effectiveness of the program, which differed by an order of magnitude.

“Both sides used substantial modeling instead of real numbers,” Chu said in an interview after the talk. “Going forward, it is important to gather as much data as possible and to use control groups to estimate the energy costs and carbon reduction benefits with data.”

Thinking globally

Chu was interviewed by Stanford Precourt Institute for Energy co-directors Arun Majumdar and Sally Benson . Majumdar asked Chu what the global community—and the United States—should be doing to address climate change.

Global collaboration and leadership from developed countries is important, according to Chu. If the United States, China and Europe set a price on carbon, they could address much of the world’s emissions without punishing emerging economies.

If instead, the United States takes an insular attitude and “a look-out-for-number-one” mentality, “it comes back and bites you,” said Chu. He added that we have seen the outcome of this mentality in recent weeks, both in terms of different populations’ ability to deal with the COVID crisis and in how police treat different sectors of society.

“The consequences of ignoring the risks of climate change is a magnified version of ignoring the warning signs of a growing pandemic or risking societal instability by allowing unequal treatment by the police to continue. We live on the same planet and like it or not, we are all in it together,” he said in an interview after the talk.

Chu’s slide deck can be viewed here (pdf) . Not all slides were shown during his Global Energy Dialogues presentation.

The next Global Energy Dialogues session will be July 7 and will feature Chad Holliday, chair of the board of Royal Dutch Shell plc. Global Energy Dialogues are free and open to all. Registration is required.

The Global Energy Dialogues are funded by the Stanford Global Energy Forum.

Explore More

Turning carbon pollution into ethanol

Stanford scientists designed a catalyst that turns carbon dioxide into ethanol, which could incentivize cleaning up emissions.

- Featured Reports

New technology extracts lithium from brines inexpensively and sustainably

A new method for extracting lithium from briny water offers a more efficient, cost-effective, and environmental alternative to traditional lithium production. It could also help solve lithium supply chain issues.

Attosecond X-ray pulses shed new light on the photoelectric effect

The method provides a new tool to study electron-electron interactions, which are fundamental to many technologies, including solar cells and semiconductors.

Can Underground Pumped Hydro Save the World?

Mark khalil december 11, 2023, submitted as coursework for ph240 , stanford university, fall 2023, introduction.

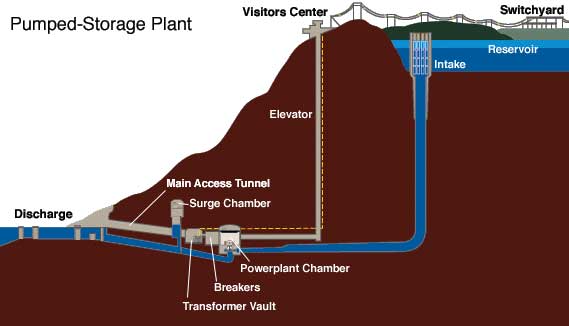

Underground pumped hydro storage (U-PHS) has emerged as an alternative solution that can overcome some of the siting and economic challenges associated with the conventional above-ground pumped hydro. This technology utilizes subterranean caverns, mines, or underground reservoirs for storing energy, typically relying on steep height differentials of water between an upper and lower reservoir to store and generate electricity on demand.

The Physics of Pumped Hydro Explained

Conceptually, U-PHS is very similar to surface level pumped hydro; the major difference is that the upper reservoir for an underground system is at ground-level while the lower reservoir is located underground, as seen in Fig. 1. [1] Underground pumped hydro leverages gravitational potential energy, using reversible pump-turbines to move water between upper and lower reservoirs situated at different elevations. The energy storage capacity of a pumped hydro storage system (E, measured in Joules) can be calculated using the formula

where ρ = 1000 kg m -3 is the mass density of water, g = 9.8 m sec -1 is the acceleration due to gravity, and h is the effective head (the vertical distance between the water surfaces of the upper and lower reservoirs in meters, and Ω is the total volume of water ready to fall downhill in m 3 . [2] The derivative of the energy equation with respect to time yields

where P is the power delivered in Watts and dΩ/dt is the flow of water through the turbines in m 3 per sec. The efficiency η, a pure number between 0 and 1, describes energy losses in the pumps and turbines. The power P' delivered to the grid can be thought of as P' = η × P.

Larger height separations h between these upper and lower water bodies (larger heads) directly correlate with increased storage capacity and power output capabilities. [2,3] By situating reservoirs in deep underground facilities, projects can leverage a thousand or more feet of head differential, allowing individual certain unique facilities to bring online several hundreds of MW to over a GW of installed capacity at a time at larger abandoned mines in some cases, with scalability through expansion of water volumes. [3-5] With the ability to go from zero power to full power dispatch in under one minute, underground pumped hydro can serve as a rapid response backbone to stabilize intermittent wind and solar infrastructure at scale. [1]

The efficiency of U-PHS is comparable to traditional pumped hydro storage, with some variation depending on the turbines used at the specific project site and its implementation details. [6] There are actually two efficiencies when considering pumped hydro systems, one for charging and another for discharging. The "round-trip efficiency" is the product of the two. The round trip efficiency rates of pumping to storage to electricity generation are on par with above-ground pumped hydro at 70-85%. [1,3] However, the relatively low energy density of PHES systems requires either a very large body of water or a large variation in height which is what makes underground systems potentially more attractive alternatives. [6,7] In addition, having the water stored underground can in some instances, reduce losses due to evaporation. [7]

Naturally, there is an extremely high variance when it comes to implementation costs, as each site has its own idiosyncratic features, which means pumped storage systems have capital costs of $600-2,000 per KW or $5-100 per KWh and 0.1-1.4 cents per KWh per cycle. [6] Underground pumped hydro, which takes advantage of natural geography and voids rather than requiring extensive dam, reservoir, and civil engineering means there is more flexibility in siting, and can often allow developers to locate projects closer to energy infrastructure and consumers. With long asset life spans of 50+ years and low maintenance requirements as system components are protected underground, projects can deliver electricity at very low costs for decades. [3]

However, the estimated costs are 1.1 to 1.3 times higher than conventional PSH plants. [4,8] Unless the market environment radically changes, returns for investors therefore seem modest but the societal benefits of lower electricity prices and better grid stability are substantial. Market incentives for large dedicated storage investments are lacking, an public-private partnerships may enable projects. [4,8] Compared to batteries and hydrogen storage, U-PHS can provide larger-scale, longer-duration storage at modest roundtrip losses, and U-PHS deserves consideration among storage options for deeply decarbonized electricity systems, given suitable geology. [4,8] Government policy and regulation changes may be needed to spur investments, as the fundamental issue is that markets lack incentives for investment in very large, capital-intensive dedicated storage. [4,8]

Other that cost issues, other important considerations for successful U-PHS implementation include understanding the drainage considerations as some sites naturally refill with water. Understanding the dynamics of water tables, or the levels where the ground will be filled with water if you go any lower is critical for the successful design and implementation of sites. [7] Despite the challenges, U-PHS could provide large-scale energy storage to facilitate greater integration of renewable energy and stabilize electricity grids. Suitable underground geology for U-PHS has been identified in coal mining areas in Germany and the Netherlands, where these risks of subsidence or seismic impacts appear low. [4,8]

In conclusion, the potential of underground pumped hydro storage heralds a transformative era in sustainable energy solutions. As an innovative approach to address the challenges of conventional above-ground pumped hydro, this unique technology leverages subterranean spaces, mines, and caverns to store and generate electricity efficiently. [4,6-8] Offering comparable efficiency rates to traditional systems and enhanced flexibility in siting are reasons underground pumped hydro emerges as a promising alternative for long-term energy storage. [4,8] However, repurposing existing underground structures, such as abandoned mines, is expensive, and despite showcasing adaptability and resourcefulness in meeting the world's growing energy demands is a capital-intensive solution that requires more granular support. As research and development continue to advance, and with successful deployments of renewables, the potential of underground pumped hydro storage stands poised to play a pivotal role in fostering a more sustainable and resilient energy landscape. [4,8]

© Mark Khalil. The author warrants that the work is the author's own and that Stanford University provided no input other than typesetting and referencing guidelines. The author grants permission to copy, distribute and display this work in unaltered form, with attribution to the author, for noncommercial purposes only. All other rights, including commercial rights, are reserved to the author.

[1] H. Chen et al. , "Progress in Electrical Energy Storage System: A Critical Review," Prog. Nat. Sci. 19 , 291 (2009).

[2] T. Kousksou et al. , "Energy Storage: Applications and Challenges," Sol. Energy Mater. Sol. Cells. 120 A , 59 (2014).

[3] X. Luo et al. , "Overview of Current Development in Electrical Energy Storage Technologies and the Application Potential in Power System Operation," Appl. Energy 137 , 511 (2015).

[4] M. Wessel, R. Madlener, and C. Hilgers, "Economic Feasibility of Semi-Underground Pumped Storage Hydropower Plants in Open-Pit Mines," Energies 13 , 4178 (2020).

[5] F. Liu et al. , "Pumped Storage Hydropower in an Abandoned Open-Pit Coal Mine: Slope Stability Analysis under Different Water Levels," Front. Earth Sci. 10 , 941119 (2022).

[6] S. Rehman, L. M. Al-Hadhrami, and Md. M. Alam, "Pumped Hydro Energy Storage System: A Technological Review," Renew. Sustain. Energy Rev. 44 , 586 (2015).

[7] X. Lyu et al. , "Pumped Storage Hydropower in Abandoned Mine Shafts: Key Concerns and Research Directions," Sustainability 14 , 16012 (2022).

[8] G. J. Kramer et al. , "Risk Mitigation and Investability of a U-PHS Project in the Netherlands," Energies 13 , 5072 (2020).

- GridTECH Connect

Pumped storage hydro, utility-scale batteries return about 80% of the electricity they store

Pumped-storage hydroelectric facilities in the U.S. operated with an average monthly round-trip efficiency of 79%, and the utility-scale battery fleet operated at 82%, according to 2019 data from the U.S. Energy Information Administration (EIA).

Round-trip efficiency is the percentage of electricity put into storage that is later retrieved. The higher the round-trip efficiency, the less energy is lost in the storage process.

With electric energy storage becoming more important as the share of intermittent generating technologies, such as wind and solar, in the electricity mix increases, EIA said storage metrics can help us understand the value of the technology. EIA’s Power Plant Operations Report provides data on utility-scale energy storage, including the monthly electricity consumption and gross electric generation of energy storage assets, which can be used to calculate round-trip efficiency. The metrics reviewed here use the finalized data from the Power Plant Operations Report for 2019 — the most recent year for which a full set of storage data is available.

Pumped-storage facilities are the largest energy storage resource in the U.S. The facilities collectively account for 21.9 GW of capacity and for 92% of the country’s total energy storage capacity as of November 2020.

In recent years, utility-scale battery capacity has grown rapidly as costs have decreased. Batteries have become the second-largest source of electricity storage. As of Nov. 20, 2020, utility-scale battery capacity had 1.4 GW of operational capacity. Another 4 GW of battery capacity is scheduled to come online in 2021, according to EIA’s Preliminary Electric Generator Inventory.

Although battery storage has slightly higher round-trip efficiency, pumped-storage facilities typically operate at utilization factors that are twice as high as batteries. Increasing durations among battery applications could shift battery operations toward services that reward longer output periods. For example, in 2015, the weighted average battery duration was a little more than 46 minutes, but by 2019, weighted average battery durations were 1.5 hours.

Related Posts

Latest Renewable Energy World News

Do the Math

Using physics and estimation to assess energy, growth, options—by tom murphy.

Pump Up the Storage

Gravitational Storage Basics

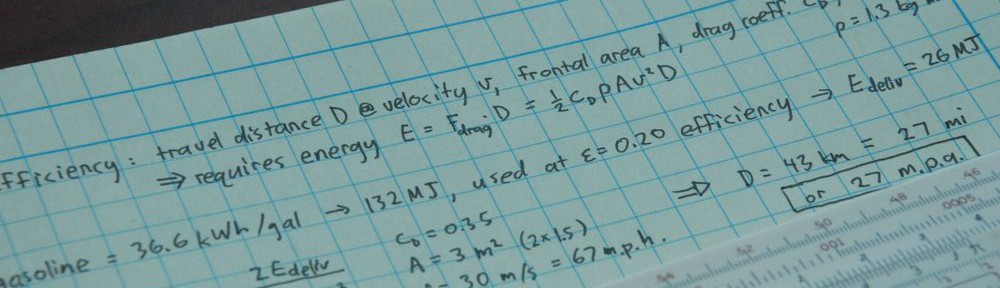

When you lift an object, you must supply a force to counter gravity (the weight of the object) and apply this force over the height through which you lift the object. The weight of an object—and therefore the force applied to lift it—is its mass times the acceleration due to gravity (application of Newton’s F = ma ; in this case, mg , where g is the gravitational acceleration, or about 10 m/s²). Work is defined as force times distance, so lifting an object of mass m a height h results in an energy (work) investment of mgh . This is called gravitational potential energy .

It is called a potential energy because it is possible to put the invested energy on a shelf—literally, in fact—to be accessed later. A dropped brick that had previously been given gravitational potential energy can do useful work, like driving a nail into a piece of wood (huge force times small distance = same work). The stored energy does not degrade one iota over time: in that sense it represents perfect long-term storage.

The idea for pumped hydro storage is that we can pump a mass of water up into a reservoir (shelf), and later retrieve this energy at will—barring evaporative loss. Pumps and turbines (often implemented as the same physical unit, actually) can be something like 90% efficient, so the round-trip storage comes at only modest cost.

Raccoon Mountain pumped storage concept.

The main problem with gravitational storage is that it is incredibly weak compared to chemical, compressed air, or flywheel techniques (see the post on home energy storage options ). For example, to get the amount of energy stored in a single AA battery, we would have to lift 100 kg (220 lb) 10 m (33 ft) to match it. To match the energy contained in a gallon of gasoline, we would have to lift 13 tons of water (3500 gallons) one kilometer high (3,280 feet). It is clear that the energy density of gravitational storage is severely disadvantaged.

What we lack in energy density, we make up in volume. Lakes of water behind dams, for instance represent substantial storage.

When water is let out from the bottom of a dam, it carries energy as if it had been “shelved” at the surface of the lake behind the dam. How does water at the bottom “know” how high the lake surface is? Pressure—which is proportional to the weight of water overhead. So let’s take a cubic meter of water, at a mass of 1000 kg, and send it through the turbine. The mgh energy in the cube of water for a 100 m high dam is (1000 kg)(10 m/s²)(100 m) = 10 6 J, or one megajoule.

If this 100 m high dam only has one cubic meter per second flowing through, it would produce 1 MJ/sec, or 1 MW. I am ignoring the roughly 90% efficiency of hydroelectric turbines to keep numbers tidy and approximate. More typically, flow rates are measured in the 1000 m³/s range, so that our 100 m dam would produce 1 GW at this scale.

So the recipe is simple for understanding a hydroelectric dam: multiply the height of water behind the dam (in meters) by ten-thousand times the flow rate in cubic meters per second to get the power in Watts.

We Need How Much Storage?

The U.S. has a power diet of about 3×10 12 W, or 3 TW. Two-thirds of this feeds heat engines (power plants, cars, etc.), at an average efficiency of 30%, delivering 0.6 TW of useful work in the bargain. The other 1 TW is direct heat (lots of this in industrial process heat), and electricity from nuclear and hydro sources. Imagining that we replace our heat engines with direct electricity and electrified transport, we need something like 2 TW of total power, accounting for some inefficiency. If you’re happier with half this, fine—a factor of two will not qualitatively change the giant scale of the problem.

The next question is: how long do we need our storage to last? In the Nation Sized Battery post , I argued that we need 7 days of storage for it to be invisible to the end-user. That is, if Americans insist on not changing any of their habits, and having zero storage-crunch outages on a decade timescale (read about the total shutdown of San Diego in a recent county-wide power outage ), then 7 days is probably not far from the mark. I got flak for this choice, but I use it again here because A) it is not all that unreasonable, B) it allows side-by-side comparison to the national battery calculation, and C) you’ll see it does not make or break the case: even one day of storage is super-hard. Divide all my scale numbers by 7 if you wish that I had used one day of storage, for instance.

Note that 7 days of storage does not literally mean that we are prepared to experience 7 days with zero input from the renewable infrastructure. Operating at 30% of the break-even amount over a period of 10 days also leaves the system with a 7-day energy deficit, for instance. This circumstance is not too difficult to imagine: a cloudy winter week over the southwest while the wind speed over the country is half its average value (means eight times less power) over the same period.

So 2 TW for 7 days means 336 billion kWh of storage capability.

First-Blush Pumped Hydro

What scale would this amount of storage require if we did a pumped-hydro scheme? One immediate scale reference is to note that we have 78 GW of installed hydroelectric power in the U.S., amounting to 4% of the target 2 TW demand. Our traditional hydro capacity could not be scaled up by even a factor of two—since the premier river sites have been plucked already.

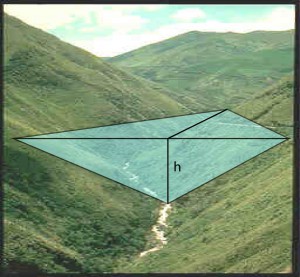

What about potential pumped hydro installations: not on current rivers, but in the mountains where we could wall off a high valley and fill it with water?

I say mountains because we need a significant height differential for pumped storage to make much sense. We won’t see pumped storage in the plains. The horizontal distance must also be minimized, so we need sharp relief—meaning mountains.

To first approximation, we can imagine mountains as lumps. They have pointy tops that point up. They are distinctly not very bowl-like. Upside-down bowls, maybe. They do, however, often produce hollows (“hollers” in some parts) ringed by arms/ridges of the mountain. Walling off the opening to the hollow allows us to fill this useless void with water. The pikas and marmots can just learn how to swim! We also need another equal-volume body of water below, to catch the water in the storage cycle.

I can’t say that I’ve studied the topography of our lands to see how many places are amenable to these grand-scale engineering marvels. I may be oblivious to the widespread existence of natural bowls perched on the edges of cliffs. Whatever the case, the 22 GW of pumped storage we do have at present presumably picked the primo spots. Instead of fussing over topographical maps, I am using the simple “hollow” model informed by my time in the mountains and staring at relief maps.

In any case, let’s not allow these details to prevent us from doing some math! Let’s say our average candidate hollow allows a 500 m high wall (1650 ft) on one end, and another few-hundred-meter wall lower down for the lower reservoir (the hollow is wider here—maybe even a vale by now—so the same volume is accommodated by less depth and more area).

Simple model for filling a hollow with water to height, h.

My model for the hollow will have a V-shaped profile, with sides at a 20% slope and the hollow floor running up at a 10% slope. Thus the 500-m-high dam wall is 5 km across at the top, and the lake extends 5 km back in a triangle. This geometry produces a reservoir 2 cubic kilometers in volume. Considering the tapering shape, the stored gravitational potential energy is 2 billion kWh. We just need to build 170 of these things. Never-mind the fact that we have never built a wall of such proportions. Or the fact that the largest pumped storage facility to date stores 0.034 billion kWh—60 times less capacity.

But let’s continue to play the game: If we indeed demanded 2 TW of power from about 170 pumped-hydro stations, we’re talking 12 GW of production capability each. This is significantly larger than the biggest hydroelectric installation in the U.S. (Grand Coulee, at 6.8 GW). Times 170.

Perhaps I was too ambitious in starting with a 500 m dam height. A greater number of smaller reservoirs would allow more sensible power stations and perhaps avoid turning the seven wonders of the world into the 177 wonders of the world (with lots of redundancy).

The energy stored in the walled-off-hollow scales like the reservoir height to the fourth power! So if we drop to 250 m height (still impressive to me, being taller than Hoover Dam), we need 16 times as many installations (over 2,500), each with 600 MW capacity. For scale, we currently have 24 hydroelectric installations in the U.S. rated at > 600 MW capacity.

Hoover Dam: 221 m high; 2.0 GW power; 2.5 million cubic meters of concrete.

I think at this point, you can see why quibbling about the need for 1 TW vs. 2 TW or requiring 2 days of storage vs. 7 days is not going break the logjam of a hard problem. Even accomplishing 1% of the requirement I have laid out would be super-impressive.

All That Concrete!

These dam walls will require a lot of concrete. A survey of dam construction suggests that the base thickness is approximately 65–90% the height of the dam. Picking 75% and tapering to a cusp, our foregoing geometry requires a concrete volume 25% larger than h ³, where h is the dam height. For our 250 m set of dams, we need 19 million cubic meters of concrete apiece. Each dam then contains as much concrete as exists in the Three Gorges and Grand Coulee dams combined! And this is the “ small ” version of our dams. And we need over 2,500 of them. I’m just sayin’.

At an energy cost of 2.5 GJ per ton of concrete, and a density of 2.4 tons per cubic meter, we end up needing 32 billion kWh of energy per dam, and 90 trillion kWh total. This over 250 times the amount of energy impounded by the dams, and represents three years of the total energy appetite of the U.S. today.

Note that I’m totally ignoring requirements for the lower reservoir.

Ample Room for Water Skiing

I’m keen now to understand what this looks like relative to our landscape. How much area will all these lakes take?

In the 500 m dam-height model, the area of the upper reservoir is 12.5 square kilometers. Times 170 reservoirs is 2125 square kilometers. In the 250 m model, we have 3 square kilometers per reservoir, or 8500 km² for the whole set. So the total necessary area scales like the inverse square of the characteristic dam height.

We also need to add the area for the lower reservoir. Since the terrain is likely less sloped lower down, let’s assume that the lower reservoir surface area is twice as big as the upper reservoir, so now we have about 25,000 km² in new lake area (both reservoirs are not full at once, but this land is no place to build a mall).

We get an area equivalent to 160 km on a side. This is the same area as Lake Erie (and more than its volume). Add another Great Lake’s worth of space to the map. No trivial affair. I haven’t asked yet where we get the water for this endeavor. Good thing water shortages are of no concern on this planet.

It is worth also comparing to the area of a photovoltaic system providing the 2 TW of average power. Such performance would require 10 TW of installed capacity (accounting for day/night, sun angle, weather). At 15% efficiency and 1 kW/m² of incident peak solar energy, we need about 65,000 square kilometers of panel—roughly comparable scales. Keep in mind that the water area is based on over 2,500 gigantic 250 m dams, each taller than Hoover Dam, and containing 8 times as much concrete. For smaller, more realistic projects, the area of water could easily exceed the solar panel area. Converting land to pumped storage carries far greater environmental impact than converting to a solar farm, so that storage concerns dominate. Wind takes substantially more land (about 50 times) than solar, so the pumped storage lakes would not rival the area dedicated to wind farms.

Variations and Scalings

We’ve relied on loads of assumptions in our exploration of the potential for pumped storage. It is easy to lose track of the choices and the impacts they have. Is the 20% slope on the sides important? How do things scale with the dam height?

In a general analysis, it works out that the number of dams needed is proportional to the total energy storage required times the side-slope of the hollow (in %, e.g.) times the slope of the hollow floor divided by the height of the dam to the fourth power. But interestingly, the total volume (and therefore energy) required for concrete only depends on the hollow floor slope divided by the height of the dam.

The result is that one 500 m dam replaces 16 250 m dams, while taking only half the total amount of concrete. Scaling therefore favors the big projects over the dinky. Of course the number of acceptable sites for the mega-projects may be too slim, while the pressure to find 16 times as many lesser sites is no walk in the park.

Total lake area scales as the inverse of side slope and the inverse square of the dam height. So, naturally, broader shallower lakes will be more evident from space. Total water volume needed just follows the inverse height of the dams.

Of course any real implementation would have a wide variety of dam heights in the set. I treat them all as the same to establish baseline numbers. Strict averages do not work due to scalings that are not linear, but this at least gives us an idea. An analysis where I allowed a distribution of dam heights would just waste my time and yours.

A common trick is to build a large feed-tube from the bottom of the upper dam to a turbine/pump located far below. This will not be easy to accomplish everywhere, but an additional 500 m drop improves the 250 m dam by a factor of 3.6, and a 500 m dam by a factor of 2.3. Doing this reduces the number of such projects needed by a similar factor (still large numbers). But don’t get too excited by this option: we still need a place to put the lower reservoir. If you give up too much height, you run out of natural walls and vertical relief, demanding a very large flooded area to catch the water.

Comparison to Real Examples

Ludington pumped storage: 110 meters; 1.87 GW; 15 hours; 27 million kWh.

Enough fooling around. Let’s compare this fantasyland to something real. We have 22 GW worth of pumped storage in the U.S., which is about 1% of my 2 TW goal. But they tend to be sprinters rather than marathon runners (typically about 12 hour run-time at capacity), so the actual storage falls short of what we need by a factor of 1500 or so. Think we only need one day of storage? Still a factor of 200 off.

The largest pumped hydro installation in the U.S. (in terms of energy, not power) is at Raccoon Mountain, in Tennessee. I owe much of my air-conditioned comfort as a kid to this facility. Sitting atop a mountain, the reservoir unloads to the Tennessee River 300 m below (technically Nickajack reservoir). The installed capacity is 1.532 GW, implying a flow rate of 575 m³/s. The upper reservoir provides an unusually long 22 hours of service, so that the volume of useful water is 45×10 6 m³, and the energy storage is 34 million kWh. The surface area of the lake is 2.16 square kilometers, resulting in an average depth of 21 m. The (earthen) dam is 70 m high and 1800 m long, from which I calculate a dam volume of about 10 6 m³—about half that of Hoover Dam.

Raccoon Mountain: 302 m; 1.53 GW; 22 hours; 34 million kWh.

What can these real numbers tell me about my simplified geometry and the guesses that went in? The main difference is that the Raccoon Mountain geometry has much gentler slopes: something like 3–5% up the “hollow,” and about 8% up the sides. We would need 10,000 Raccoon Mountains to meet my baseline energy capacity—although we could scale back on power per unit. This becomes 50,000 if you can’t use the trick of dumping to a reservoir far below. For 10,000 replicas of Raccoon Mountain, the total lake area (including the area of the lake below) is about three times the size of Lake Erie (Lake Superior-size). The dam volume is about one-fifth what we had before, becoming comparable to the extent that the deep-drop trick is not employed. The total volume of water sequestered is comparable for the two cases (because this is just mgh , and our baseline had h = 250 m, while Raccoon Mountain uses h = 300 m).

Re-purposing the Hydroelectric Infrastructure

If at any point in this development you thought, “wait a minute: why build all these giant dams in the mountains when we’ve got large lakes and dams already, with water already delivered to the doorstep?!” then you are not alone: I wondered the same thing.

The first note is that our installed hydroelectric capacity in the U.S. is 78 GW; a factor of 25 short of the necessary full-scale capacity.

The next note is that water flow is not always available to realize the capacity of the installed power. For instance, the U.S. hydroelectric plants produce about 270 billion kWh each year, which is only 40% what would be delivered if all dams ran at 100% capacity all year round. For example, Hoover Dam has an annual production of 4.2 billion kWh, which is 23% of what the 2.08 GW installed capacity could churn out in a year. Even the mighty Columbia fluctuates enough that the Grand Coulee dam only realizes 35% of its capacity.

These points are relevant because in order to achieve the necessary 2 TW power output, we need to multiply the hydroelectric capacity flow by a factor of 25, or a factor of 60 greater than the average flow. We might predict a few erosion problems here and there.

Let’s Do It Anyway!

Let’s not be wimps. Let’s just beef up our hydroelectric capacity at the developed sites and ask whether we have enough energy storage behind the dams. One way to look at this is to figure out how much power would be generated if all lakes impounded behind hydroelectric plants dropped by one meter over a 24 hour period. Computing this for each dam based on each lake’s surface area yields a total of 170 GW of power. We need more than this. Our demand for electricity alone in this country averages 450 GW, and of course we’re shooting for about four times this to cover all our energy demands.

The upshot is that getting sufficient energy out of the current infrastructure would require draining each reservoir by a little more than 10 meters per day. But as the lakes drain, the surface area shrinks, so that my ten meter estimate is too low. Additionally, many dams will tap out once we get beyond the 10 meter range, and the fact that the energy delivered drops as the height of water drops reduces the capacity further. Using the volume reported behind each dam, I find that draining all reservoirs over a 7-day period delivers a power of 500 GW. Of course dams are often serial along a river, so we get to re-use water along the way. This will give us a factor of several, and put us close to our need.

But let’s not forget that our scheme here involves emptying all the lakes and rivers of water, and at a rate far in excess of what the channels are accustomed to carrying. It’s an extreme maneuver.

Drain the Great Lakes

While we’re having “fun,” let’s see what we could get out of the Great Lakes. The upper four lakes are all at essentially the same elevation (6 meter drop from Superior to Erie), while there is a 99 m drop between Erie and Ontario. We call this Niagra Falls, although only half the drop is developed across the falls proper.

If we drained one meter from every upper lake, we would get 54 billion kWh of energy: about a sixth of the target capacity. If performed over seven days, the flow would be 375,000 cubic meters per second, or 125 times the normal flow over the falls. Now I’d pay to see that! But I would first want to visit every town along the St. Lawrence River one last time.

If we tried to trap the water in Lake Ontario so-as to spare those downstream of the wrath, its level would rise 12 meters (39 feet). Watch out Toronto & Rochester!

The pipe delivering this water to the turbines would have to be over 125 meters in diameter (or 160 tubes each 10 m in diameter) to limit the velocity of the water through the pipes/turbines to below freeway speeds! What fun.

Am I Insane?

Why do I always do this: pick a challenge and show how ridiculous it is to solve the problem by a monolithic approach? Maybe I’m the one being ridiculous!

This tendency is a reflection of my quest to understand how we might face the tremendous energy challenges ahead. The first step is always to assess the potential of a solution relative to the full-scale demand. If it wipes the floor with an excess capacity, then great: it is inarguably a no-brainer go-to solution. If it comes up short, that’s very informative too.

Yes, a diverse portfolio of a half-dozen inadequate solutions may be able to add to an adequate solution. But a half-dozen woefully inadequate solutions cannot pull off the same stunt. So far, my quest keeps turning up the woefully inadequate type. The scale of fossil fuel replacement is so daunting that we very quickly get into trouble when putting numbers to proposed solutions.

A common reaction to the Nation Sized Battery post—especially on the Oil Drum Forum —was that I was being silly by considering a full-scale lead-acid battery, and that pumped storage was such a more obvious solution to the problem. It was not obvious to me, but I had not yet done the math. The fact that just one of the “small” dams considered here has as much concrete as the Three Gorges and Grand Coulee dams combined is humbling. I would be impressed if we made one. I would be astounded if we made 25. And this just gets us to 1% of our need (or 7% if you still bristle at a 7-day battery).

It is clear enough that pumped storage exists and works quite well in certain locations. But demonstration does not imply scalability, and scaling the existing installations did not deliver a radically different answer (in fact, demanding more installations). The enormous scale I calculate means simple factors of two or even ten here and there do not change the overall flavor of the conclusion.

Let’s be clear that I am not making any claim that large scale storage at the level we need is impossible . But it’s far more daunting than almost anyone realizes. It’s not a matter of “just” building up when the time comes. We could easily find ourselves ill-prepared and suffering insufficient energy supplies, intermittency, and a long, slow economic slide because we collectively did not anticipate the scale of the challenges ahead.

Acknowledgment: Thomas Tu contributed research on hydroelectric installations, consolidating capacity, height, and capacity factors for dams, along with surface areas and volumes of impounded lakes.

Views: 56391

117 thoughts on “ Pump Up the Storage ”

There is a proposal on the table in Germany to lift a large piece of stone instead of water. The claim:

“The key advantage of this approach lies in the extraordinarily large amount of energy that could be stored and the relatively small investments compared to a similar hydro storage.” Like your article, they tak about storing days of the nation’s electricity demand. It would also need less space than water pumped storage.

http://eduard-heindl.de/energy-storage/index-e.html http://eduard-heindl.de/energy-storage/energy-storage-system.html

They plan to get funding to build a pilot.

If that worked, would we re-enter the stone age? This is so crazy I don’t know what to say. Density gains you only a factor of three or so. And stones don’t flow very well, so its hard to get hundreds of meters of height like you can with water. I didn’t think they smoked much marijuana in Germany…

The specific plan (click on the link) is to use an underground water resevoir to lift a vast stone piston. The energy is in the potential energy of the stone, which provides hydraulic pressure on the water. You get a multiplier from the density, as you point out, and also might find it a lot easier to find suitable sites.

Stone just isn’t that big a help and as tmurphy rightly pointed out, it’s a solid whose size and shape is generally fixed. Water can transport itself great distances vertically or horizontally and it’s quite malleable. Self-malleable.

It also occured to me that to have a solid – solidity aside – give you an order of magnitude density improvement or more, your choices for starting points are e.g. silver, lead, and thorium. If that’s a little too rich, toxic, and/or radioactive for your blood, you can trade down all the way to iron at 7.9g/cm^3, but you’d have to scale up the height or the amount to compensate.

I’m concerned about what it will take to implement the storage it would take to even out the generation from wind, solar, and other intermittents, even if the storage is co-located with those facilites. Economies of scale suggest that you wouldn’t want to.

This “piston” idea also completely omits the problem to produce a high pressure resistant hydraulic-grade seal around the stone slab. Stone doesn’t float, so if the piston doesn’t seal perfectly, you end up pushing a ring of water upwards. The paper only states “the piston is sealed”, but nothing about how they want to achieve that in such a large scale.

Once again, a great analysis! I was reasonably convinced already, by my own even rougher numbers that this was a no-go, but your explaination bought it home very vividly.

I guess the next topic should/could be doing the math on large scale compressed air/gas storage. Hey!, maybe we could use all that sequested CO2 and kill two birds with one stone! (actually, could we? hmmm…)

How about 70,000 GPM Peaking Plants instead: http://gigaom.com/cleantech/a-new-energy-storage-option-gravity-power/ http://www.gravitypower.net/

Really enjoying all the posts! Are you familiar with David MacKay’s ‘Sustainable Energy – without the hot air’: http://www.withouthotair.com/ ?

See my response to J Anthony below, which addresses this concept. Glad you got the 70,000 number too. David MacKay is a hero to me. His book is one of the few links in my blogroll.

There are a few good micro hydro electric generators that work with low head. Might it not be better to generate when needed rather than store. Barring drought this might make more sense.

I guess i question the total size, requirements based on your 500m assumption. if u assume something like 1500m or so u drastically alter the issue As the height scale is X^4 that minimizes our requirement by a factor of 81.

Heck if you used something like Flagstaf, AZ =>Phoenix, AZ thats about a 1800m.

Correct me if Im wrong, but via your design of 500m u said that there was a 340 cubic km of water requirement. (2 cubic km per each of the 170), divided by 81 gives us ~4.2 cubic km of water. if u assume we build this as a dug lake height is 1km in depth your talking about a space of only 2 by 2 km.

If u build the plant at the bottom edge of this new “lake” it seems “reasonable” we could dig this out. now I’m ignoring what u do with the waste water/inflow water, but it seems reasonable that its not a always needed and u COULD just create an outflow river and pump in sea water from the gulf of California. I’m not saying that’s an efficient measure electricity wise to build up the energy, but as far as actual storage it seems like a doable thing.

You can’t scale volume the same way: the factor of 81 would apply to the number of dams, but the volume would just be reduced by a factor of three.

I shied away from the 500 m mega project, you ran the other way!

For 1500 m projects, you would need two; the volume of water would be 55 cubic km each (bigger than any reservoir in the U.S.), and the concrete needed for each dam would be 4 cubic km (about 400 times as much as in Three Gorges). Now I know why I ran toward smaller projects: I have a tendency to follow the slope from fantasy to practicality.

Great post. Very educational applied physics. Pity our politicians can’t do math

Would you be interested in doing the numbers for solar powered satellites?

http://in.reuters.com/article/2011/11/13/idINIndia-60496820111113

Obvious problems are the sun not shining at night, collecting and converting the energy in space using mirrors or solar panels, microwave atmospheric absorption and losses from the rectenna collection.

Regards, Gary

Uh, a main point of SPS is getting around “sun doesn’t shine at night”, because with the right orbit there is no night. Also no weather.

While I’m commenting: “Wind takes substantially more land (about 50 times) than solar, so the pumped storage lakes would not rival the area dedicated to wind farms.”

Though OTOH wind is far lower impact on the land it uses than anything else; you can still use the land as farmland or preserve. It’s not shading the land like solar or drowning it like water. And some of the ‘land’ is off-shore ocean. (And how much land is used presumably depends on the wind speeds.)

Wind does kill birds, a lot of birds, this is by count under the rotors at every location where wind turbines have been installed. This makes it unsuitable for many locations and shows that it is not risk free or low impact.

David MacKay makes the point that domestic cats take a far, far, far greater toll. Now if windmills were also cute!

I think the fantastic cost rules anything like this out. The advantages in being in space are energy generation factors of perhaps 2-5 at most I guess. But the cost of getting it into space is many many orders of magnitude greater (and you’ve got to maintain it). It just isn’t going to happen. Someone else can do the math if they like.

Well put. Anything involving a lot of mass in space is going to kill the economics. And getting the energy down to Earth is anything but easy—despite what enamored proponents might say.

But solar from space isn’t the subject of this post, so I will not continue this thread—though I will add that Chris Nelder offered his link on the topic .

Space based energy systems will never work out due to the energy cost of lofting them into orbit, it does not scale. I believe that it took 10% of the production of the US for 8 years to put a few men on the moon. The rocket that did that was the most powerful energy converter that mankind has ever produced and used out side of the bomb.

Brilliant post. I once calculated that I’d need a chunk of concrete the size of my two-car detached garage, lifted to a height of 130 feet to supply reliable power to my house from the wind and solar resources available. Imagine a neighborhood full of those! (however, you could use the same tower for the turbine and to hoist the counterweight…)

[edit: counterweight just means weight]

Energy storage is of course needed because the most promising alternative energy sources aren’t on all the time, and don’t have their peak production in phase with peak demand. Electricity generation is of course the most useful goal of energy storage, but I wonder how much demand could be shifted to other storage. The specific example I have in mind is for air conditioning and refrigeration: could we make ice during peak generation and melt it during peak need?

The Dutch were considering a scheme (can’t find a good link) where they built pumped storage at sea. Basically you encircle a huge area of sea and then pump the water out when you have excess electricity and then let it back in again when you need power. If you were lucky it also became a source of tidal energy. Less planning issues (perhaps, what about international treaties?)than land based pumped storage and your volume scales well with wall circumference, but a massive initial investment. Still they thought they had the experience from building dykes. I’d be interested to see some number on that idea…

Who will build and repair that? Aquaman?

At least we know for sure they DO smoke weed in Amsterdam…

actually, you could “just” anchor a huge ballon to the bottom of the sea, and compress air into it – against the pressure of the water, so it would even be gravity storage in a way! Having a soft, submerged container would lessen some of the problems with waves shaking your structure apart.

Problem is, compressing air is less efficient than pumping water.

A company that is developing this technology claim a 70%+ operating efficiency.

http://hydrostor.ca/home/

When you compress air, it heats up. In an underwater balloon, it will cool off. That represents a sizable loss of energy.

This is a generic issue with compressed air, and whether underwater or not, the compressed air will heat to above ambient and then have to cool back down to ambient. Sure, it’s a little worse if the storage is a bit colder then the ambient air, but this is not a huge loss for the sorts of temperatures we’re talking.

Also, in any compressed solution, charging slowly enough prevents heat-up-loss from being a serious loss.

I heard about that. I think they concluded that the costs would be too high, but I’m not sure. They called the idea “energy island”.

Here’s another “magic bullet” I keep hearing about — CAES.

Compressed Air Energy Storage has some problems for sure – heat buildup being one of them. But both heat and pressure can be used for energy. In an earlier post, you briefly talked about household level compressed air storage, and it had some advantages. I’m sure I’m not the only one who’d be interested in seeing your thoughts air pressure being used for grid scale storage.

In the scenarios I’ve seen, a man-made underground cavern is used to store the air pressure, plus surplus heat in a pebble bed (in some designs, temps go over 1000 degrees F.) The air pressure can be used to drive a turbine or a modified steam engine (as an example), This will sound counterintuitive, but the heat has to be used to keep the turbine/engine from freezing up as the air expands. Some existing CAES systems use natural gas to heat the expanding air.

I hear that the hard part of building the cavern is just drilling through the cap rock. After that, water jets can hollow-out a large volume cheaply and quickly. But I’m no geologist.

What’s your opinion. Is CAES just more noise or something to start investing in?

I enjoyed your article on Peak Oil and pumped hydro storage. If the US is to survive the looming end of cheap energy then we need to localize as much as possible. The most local you can get is your own home.

First – Build super-insulated, tight homes that use much less energy.

Second – Install solar, wind, or whatever is next at the home site to supply its energy needs and then some.

Third – Store excess supply. Here is where I think pumped hydro may work in many areas. I have a 300 foot elevation difference on my rural property. If I have a 1 Kw excess capacity in my solar array (and five hours of sunlight) I can use 5 KwH to pump water to a tank at the top. When I need that potential energy I can let the water drive a micro-hydro generator at the bottom. If it’s only 80% efficient I’ll get back 4KwH at night. Owners without a handy water head could use a grid-tied system (or compressed air or something else) to store their excess.

By having homeowners energy self-sufficient, brownouts and blackouts become an historical footnote. Local homeowner energy production is clean and non-polluting. Large enough systems could power personal electric transportation. Add local farmer’s markets and industries and you’ve just about made the transition to a post-oil world.

I agree mostly although instead of seeking energy-sufficiency on the level of individual homes, it makes more sense at the community level. An energy-efficient community with a small CHP (combined heat and power) plant, fueled with sustainable biomass, and an array of wind turbines and perhaps solar power installations. You don’t need to achieve 100% sufficiency, the important point is that load on the the far-distance grid can be reduced substantially, perhaps by an order of magnitude (don’t forget that this starts with efficiency and conservation). The remaining problems will be a lot easier to solve.

Installing more hydro reservoirs is emphatically not the answer. The environmental and social cost of large scale dams is steep. There are other small-scale solutions to the storage problem. Some cities store electricity from night wind in the form of ice underground and use it to cool buildings during the day. There are also some approaches to storing solar heat (see http://www.slideshare.net/amenning/solar-energy-9778330 ). A single comprehensive solution, such as explored in the blog post, is simply unrealistic but that is really no reason for despair. A sustainable energy infrastructure will have to be diverse, scalable and decentralized. http://www.slideshare.net/amenning/

Hydrogen of course has some promise as a storage medium. Maybe that will be the topic of the next post?

Excellent article as always, and a little depressing. Need to brush up on my camping/backpacking/survival skills.

If in fact we need “65,000 square kilometers of PV panel” has anyone (winking at you) ever measured the area of southern exposure roof tops on home across America? PV Panels are nice, but I was looking at something the other day or month that was a PV shingle. Hence you would cover the entire roof with this PV shingle (like other shingles but with pv properties). I believe it was CIGS like and had lower efficiency % but higher area coverage and cheaper price (maybe).

Of course this would mean that all homes would have them and then be tied onto the grid with sell back and such. Hard in the cities where whole buildings are in the shade most of the time. We will still need all the hydro we got and some PV farms in the desert and wind farms in the midwest.

That was the promise of thin film PV. It has not worked out so far but it may be possible with three layer films.

Good analysis, proving the grid storage problem has not been solved.

Checkout GravityPower.net they are boring holes for a pumped storage solution with a smaller footprint.

I throw in some analysis of that, as well as a second angle on our host’s problem, here. http://mindstalk.dreamwidth.org/298952.html

It’s a clever idea, but scaling up to the 7 days our host wants would take $5 trillion just for the material cost of pure concrete pistons, never mind manufacturing or drilling costs (for 1-2 kilometer shafts), or the iron — 20x more expensive — in their designs. Really, we’re talking tens of trillions.

BTW, the water in their system is just a hydraulic, the real storage element is a 200 meter tall piston or iron and concrete.

My idea is to ignore mountains and simply build artificial Great Lakes propped up by rammed earth. I’m not sure of the cost, but I have lower bounds on the scale needed, about 100-1000x the mass of the coal we burn every year, never mind the engineering of 100m tall (or 1000 m tall) enclosures.

An interesting fact is that earth weighs around 2,000,000 pounds per acre per foot. So it takes a lot of energy to move it around and ram it, more if you have to dug it out prior to the moving and ramming.

I wonder what would be the energy cost of draining rocks instead of building dams. If we can’t build the walls for our reservoir, let’s make a big hole in the ground 😉 Note that I’ve no idea how deep we could go before it would get too hot.

Also, I wonder if we really DO need so much storage. If solution could be global, we wouldn’t have to care about PVs not working during night hours — the other half of this planet will be in the sun at the same time we sleep. How much power do we lose when transmitting it to another hemisphere and could something be done here to improve efficiency? Or are we doomed 🙁

A global energy grid has been proposed – google for Project Genesis. This article by Stuart Staniford has a quick summary of the idea, mentioning losses, costs and so on:-

http://www.theoildrum.com/node/3540

It’s a long piece, so just search within the page for “Project Genesis” if you don’t want to read the rest. My take-away: a global grid is technically and financially feasible (just).

Nuclear power.

End of story.

We already generate something close to 50% of our power with nuclear in some areas of the country. Scaling up by doubling or tripling the number of reactors is quite doable in a engineering sense. The waste problem can be drastically reduced if we resumed reprocessing. Left over waste can be sunk into mile deep bore holes or dropped into the marianas trench. In any event, storing the waste has to be easier than building enough hydro storage and solar capacity to cover half the country.

Wind and solar are great. I am having 4.3 Kw installed on my roof. But to seriously run an energy economy the scale of ours without fossil fuels, there is no option other than nuclear. Each post I have read here on different schemes for trying to make solar or wind work just reinforces this fact.

Such certainty. Nuclear is a good stable baseline, but can’t follow demand fluctuations and does not represent a storage solution for the renewables that we will no doubt continue to incorporate. Nuclear can offset some of the storage need (factor of several?)—and that’s useful. But nuclear isn’t all that.

Nuclear is not normally used for to load follow, but that is largely an economic decision. It is cheaper to run them 24 hours a day. French do ramp the power of their NPPs up and down and that is the reason why their capacity factors are lower than in US, for example. (They have to since most of their electricity is from NPPs.) There are some technical issues involved, but some reactor designs have less of a problem with those than others. In principle, there is also no reason why you couldn’t use the power NPPs produce at night to produce some useful liquid fuels for example.

Fissionable material is also a finite non-renewable resource. Nuclear power plants are already consuming more uranium/year then what can be mined. http://en.wikipedia.org/wiki/Uranium_depletion It has the same problem as fossil fuels in that we will run out of it eventually. Leaving a waste product far more scarier than CO2…

Although some do claim there is enough uranium to be found in the ocean to outlast the lifetime of the sun, but no one is extracting uranium from ocean water at this point, so I guess it’s all science-fiction for now.

I was flooded with comments about nuclear, which would send the discussion about pumped hydro way off track. I’ll have to dedicated a post to nuclear sometime soon.

Nuclear as in thorium reactors as proposed by Hansen and others is a good source for energy, a lot of energy, safely. They can run on our current nuclear wastes plus thorium which is rather plentiful and their wastes products do not last anywhere as long. Plus twin byproducts of them are that they can produce Rare Earth elements as bi products and do not produce bomb elements. To bad reactors have such a bad name as these are very different from what we are using at the moment. True as in all reactors they provide base load power very well but not peak load easily. Their cores do sour the same as the reactors we currently use so peak power is difficult but for a system it is not an issue that can not be managed.

Great article! Once again You put science agains wishthinking and science wins.

I hope You write articles on other methods of storing energy.

As for solar energy, there has been a major breaktrough in solar energy production. In Spain, they can produce solar energy even at night 😉 http://www.freerepublic.com/focus/f-bloggers/2494075/posts

Regardless of storage form, electrochemical or pumped hydro, if the “national battery” is that which can be quickly charged and discharged (depleted and refilled) then perhaps it should be sized for, say, one day at 2 TW, since as Dr Murphy states the battery/hydro source is really a “sprinter”. Then, for the rare or even freakish outages requiring backup for the additional six days, fall back to the less efficient hydrogen cycle using electrolysis and fuel cell (or gas turbine or other combustion engine), or even fossil fuels. In these rare events the low efficiency or emissions from H2/CNG matter little. In this case the split for the “battery” is 48 billion kWh, and 288 billion kWh sourced by H2/CNG. Using 40% efficient turbines would require 256 billion liters of liquid H2 (10 MJ/liter) standing by, less for fuel cells. By comparison the US Strategic Petroleum Reserve holds 115 billion liters.

NREL seems to have been exploring hydrogen back up scheme for solar and wind for some time. http://www.nrel.gov/hydrogen/proj_wind_hydrogen_animation.html Some do-it-yourselfers have also gone with a solar powered battery-hydrogen hybrid storage backup scheme, using the H2 to run them through the winter completely off the grid *and* power an H2 converted car. http://www.scientificamerican.com/article.cfm?id=hydrogen-house&page=2

It is the physical nature of managing hydrogen that stops any system in its tracks that attempts to use it. The efficiency or the amount of use does not matter, Hydrogen’s physical properties make it far to difficult to handle in any scale that we are talking about. It is a non starter in any application that does not require a high graveametric energy density. This limits it to rockets and related uses.

There is a firm in San Francisco working on pulling buoys to the bottom of the bay to store power. I suspect that even if their approach works, you couldn’t scale it up due to the cost of materials, though you do get a little boost from tides. However, this approach could be used for storage at some island locations that couldn’t be part of a larger grid and don’t have the land area for pumped water storage.

The point with the rock lifting concept is: The capacity grows with the 4th-power, the cost with the 2nd-power of the radius. Resulting in a price proportional to 1/r², this means, you can build infinit cheap storage as low as 1$/kWh!

Careful not to get carried away with talk of infinite cheap storage. Scaling arguments can be taken only so far, even when they are accurate.

While I’m not saying the concept of a “nation-sized battery” can be transposed anywhere else, there is already one such “device” working pretty well as we speak. Hydro-Québec’s 26 large reservoirs can store up to 170 TWh of energy (one year’s worth of electricity). Volumes of water and land required are massive (figures for the 5 largest reservoirs: http://www.hydroquebec.com/learning/hydroelectricite/gestion-eau.html ) but the system it could accommodate more must-run renewables if needed on top of the 37 GW hydro capacity already deployed (~1 GW deployed + 2.5 GW scheduled for completion before 2015).

I followed up on the hydraulically-supported falling weight storage system, and found what seems like a more practical version than the German rock: Gravity Power Systems LLC: http://www.gravitypower.net/ with 51 min video: http://www.youtube.com/watch?v=CujxJFXwOns proposes hydraulically supported falling weights in 10m diameter vertical shafts 2000m deep, to provide 150 MW for 4h storage time; groups of 8 shafts would give 1.2 GW for 4h on 3 acres of real estate. Building time of 3y (per 150 MW unit?) is estimated. The company is just prototyping now, proposing commercial systems in 2014. Hoped-for cost $1/watt ($1000/kW) for 4h storage (all this is on the video linked above). Advantages over pumped storage are claimed, a primary one being real estate. How would this compare with the Tom Murphy analysis?

Is it a cute idea? Sure. Can it scale? Let’s see. Based on the information at the provided link the larger system (10 meter diameter tubes) provide 600 MWh per tube (I confirm this is the ballpark expected). To compare to the pumped storage evaluated here, we need 560,000 tubes, 2 km deep, 10 m diameter. This is the same amount of tubular excavation as a subway tunnel that would criss-cross the U.S. about 250 times, or go three times the distance to the Moon. Wowie.

We need a water volume of 88 cubic km, which is 8 times smaller than our 250 meter dams require, or 5 times smaller than the 10,000 Raccoon Mountain installations. The land area is small-ish, at 700 square kilometers.