A Report on Industrial Visit of Composite Textile Mill

Last Updated on 22/05/2022

A Report on Composite Textile Mill Visit

Naha N Hasan B.Sc. in Wet Processing Noakhali Textile Engineering College

Dragon Sweater (BD) Ltd. Mia Bazar, Chouddogram, Comilla

Introduction: Industrial textile mill visit is one the important element of professional education especially for textile engineering education. By mill visit students can learn about textile factories and mills, the production cycle, and the roles of textile workers.

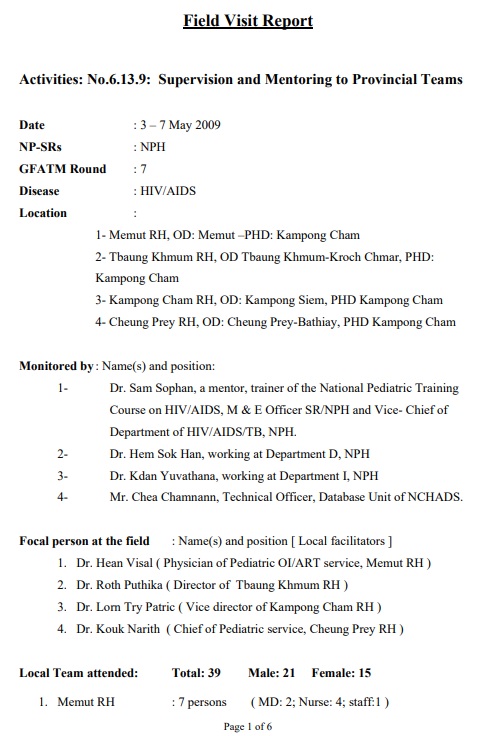

Organogram of Composite Textile Mill:

Administration

Floor In-charge

Flow Chart of Production Process:

Light Check

Winding Section: Following types of yarns are processed here

- 100% Acrylic

- 100% Cotton

- Nylon Cotton

- Feather yarn/ Sheenal

- Highly loop

- Different melange

These types of yarns are identified hand feeling and visual appearance. Here dyed yarns in skein form are wound on cone of 3/4 lbs. The rpm of the motor of winding m/e is 1400. 8 cones can be wind at a time. The dia of hexagonal frame is 29”. Here non precession winding is done by the surface contact rotation of grooved roller. Sometimes 2 or more plies of yarn wind in the same cone. The drive mechanism of this machine is rotary cylinder drive.

Knitting Section: Following parts of sweater are prepared in the flat bed knitting machine on the fashioning technology.

- Lace, Rope etc.

Here following gauge are available and following yarns are feed:

3GG→5/6 Ply 5GG→3/4 7GG→2 12GG→1

Latch needle are used here.

Different Parts of the Knitting Machine:

- Gear handle (body gear)

- Stand brush

- Yarn controller

- Side weight

- Weight stand

After preparing the yarns are attached to represent the different parts.

Green→S Red→M Yellow→L Black→XL White→XXL

Following designs are produced:

- Single jersey→ on the body, sleeve

- Rib 1×1 2×1 2×2 etc.→ Wrist, cuff, body, sleeve, neck

- Segger→ body, front part, bottom part

- Pine apple→ on the front part

- Cable→ on the front part

- Purl → lace, body

- Color stripe

And many of the designs as to the buyer choices.

Linking Section: Here different separate parts of the sweater are joined together. Acrylics, Cotton, Melange yarn are used. 3GGG, 5GG, 7GG, and 12GG machines are available here. The motor of linking machine is 1420 rpm, 50Hz, ½ HP, 110/220V. Sometimes to produce design on the body stitching is done by linking machine.

Stitch type→ 101 4 over 1 overlocking machine are used to protect the seam at shoulder, neck.

Stitch type→ 406 Seam class 1→Arm hole, body joining Seam class 4→Neck, collar joining Seam class 2→Lace, Zipper joining

Continue Section: While producing of color stripe or finishing of knitted parts there remain extended yarn. In this section these types of uncut yarns are removed manually by cutter. The extended portions of the stitch are joined on the fabric by needle manually.

Light Check: There are hole on prepared sweater parts due to needle miss or hung weight or during narrowing. To find out different faults light checking is done by wearing sweater parts on dummy shape. Then faults are identified and marked by yarn by knotting.

Mending Section: The holes on the sweater are filled here manually by the latch needle. Cotton or acrylic yarns are used to carry out this operation.

Sewing Section: Here versatile tasks are done by the following machines.

Single needle lock stitch machine: In this machine attachment of fastening device zipper, size level, care level are done.

Stitch type 301 Bar taking machine: Frequent no of stitches are sewn on certain place for reinforcements. Usually it’s done on the bottom of the body and armhole joining. Stitch type 103

Button holing machine: Button holing is done by this machine on the sweater. Again the side of button hole is sewn here.

Button attaching machine: By this automatic machine button is attached on the specific place. Generally 2/4 hole button is used. Stitch type is 104

4 over 1 overlocking machine: Such machines are used to protect the seam at shoulder, neck. Stitch type 406

All this machines are of Jucky Company. 2 ply Cotton, polyester yarn are used here.

Washing Section: The aim of this section is to remove the ambient dirt, dust, oil spots during processing and also to soften the sweater. Usually this process is done by applying

- Surf excel→250gm

- Jet detergent→250gm

Time and Temperature

- 100% Acrylic→60 C 25 min

- 100% Cotton→70 C 25 min

- Mixed Fibre→70 C 20 min

There temp is raised by steam. After washing, rinsing is carried out for 2 3 mins. In the case of softening 500gm Softex are applied. To remove the hardness of the water oxalic acid are used. Otherwise it create iron mark on light or white colored goods. After washing to squeeze excess water the wet sweater are run on hydro extractor for 5 6 mins.

At last drying is done on dryer.

- 100% Acrylic→25 min

- 100% Cotton→45 min

- Mixed Fibre→30 min

Ironing: It’s just to recover shrinkage , size and to have good dimensional stability. Steam of 120 C is applied on the different place of the sweater placing ply card of specific size on it. It’s applied for 2 3 mins from the 2.5 inch above by the iron. Ply card are prepared according to the different of sizes that supplied by buyer.

Pre QC-1 and Pre QC-2: Here two steps of quality checks are done before final check. Uncut threads are removed, mending is done if required. Here clearing gun is used to remove oil or light spot. Hence volatile solvent named air brush water is sprayed. Its application is below 5 mins to avoid harmful effects.

QC Check: Here following measurement are rechecked besides the checking of seam joining/ strength.

- Active chest

- Body length

- Sleeve length

- CB to Sleeve length

- Neck height

- Back Neck drop

- Wrist height

- Cuff height

General Tasks:

- Removal of uncut thread of the sewing section

- Mending on hole

- Zippers on accurate line

- Different spots

- Accurate weight Button, levels are on accurate place

- Dissimilarity on shade on sweater

Packing: After super check the sweater are folded. Hangtag is attached and packed on polybag. Usually hangtag, ball pin, polybag etc are supplied by buyer.

Cartooning: It’s done manually. Cartoons are supplied by buyer which contains a lot of information. Sizes of the cartoon are 810mm×470mm×260mm or so on. The blaster of sweater is of 12 pieces and so on maintaining following.

- XS→2 pieces

Net weight 10kg Gross weight 11.kg so on Blasters are prepared according to size ratio, color or buyer choice.

Other Section:

Dyeing Section: w/v gm in 100 ml of water v/v cc in (100-cc) rest of water The stock sol n are prepared by the applying the following formula. For the %, the formula can be written as,

Required CC = (w x p)/c ml

Where as, W = wt of the sample P = shade % C = stock soln %

Again for the g/l, the formula can be written as,

Where as, W = total liquor (lit) = (wt of sample x L)/ 1000 ml P = recipe amount in g/l C = stock sol n %

Again for the bulk production the formula can be written as, Required reagent = (material weight x recipe amount %) Required reagent = (total liquor liter x recipe amount g/l)

Here, Sample weight is → 5gm Dyestuff stock sol n → 0.1% (.5gm on 500ml, 1gm on 1000ml) Chemical stock sol n → 1.0% Dyeing is carried out → 9 C × 20˜25 min (atm pressure) M:L→1:40 (200ml)

Addition or subtraction of color is done by%. In the cases of re-dyeing additional % is counted.

Generally primary colors that are used

- Yellow 4GNT (light)

- Golden Yellow BRT (deep)

But for the Black

Chemicals T-PAN Leveling Agent [(Σall syestuff-1.8) %] AN Auxiliary To maintain PH→4, 10CC CH 3 COOH are added on 25 liter of H 2 O.

100% Cotton (white) After scouring properly BF 70→ 0.5gm/l White BYB→ 0. 8%

Color out NaHSO4→ 5gm/l NaCO3→ 2gm/l

Cold wash 01 NaOH → 0.5gm/l or NaCO3→ 1gm/l H2O2→ 2gm/l BF 70→ 1gm/l

Cold wash 02 HAC→ 4% H/S→ 4%

100% Cotton Soaping (98oC x 10 min) BF 70→ 1.0gm/l PLG 1500→ 0.5gm/l EA 20/10→ 0.5gm/l NaOH→ 1.5gm/l H2O2→ 2.5gm/l

Cold wash 01 HAC→ 0.5gm/l (30 o C x 10 min)

Hot wash H/S 10→ 1.5gm/l 90 o C x 20 min)

Cold wash 02 HAC→ 0.5gm/l (30 o C x 10 min) 100% Cotton Dyeing at 40 o C ˜ 60 o C

Steeping NaOH→ 0.5gm/l or NaCO 3 → 1gm/l (98 o C x 50 min)

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.

Share this Article!

Related Posts:

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Notify me of follow-up comments by email.

Notify me of new posts by email.

- Real Estate

Home » Report Templates » Free Industry Visit Report Templates (Excel / Word / PDF)

Report Templates

Free industry visit report templates (excel / word / pdf).

When an individual visits the industry whether he or she is a student or an employee, they need an industry visit report template to create a visit report. This document contains a detailed summary of the visit organized in a sequence.

Table of Contents

How to write an industry visit report?

Here are the steps to write an industry visit report;

Introduction

In this section, provide the introductory information about the event including;

- Who proposed and organized it

- Complete designation of the facility you’ve visited

- The name of your college or company

- The names and positions of people who played a significant role in organizing and implementing the event

- Faculty members who are associated with the students or employees

- Total number of people involved in it

Details of Visit

Here, you need to provide the following details about the visit;

- The timeline of the visit

- Point-by-point detail of every part of your journey

- Where and when you started

- What industries and facilities you’ve visited

- Where and when you attended seminars

- When the event ended

- When you come back

Detailed descriptions

Describe the important stages of your visit in detail. In case, you have attended seminars then specify the following;

- When and where they took place

- How long they lasted

- Who conducted them

- What they were about

- What you’ve learned

- Your general impressions

In addition, if you have visited any specific places then mention the locations, staff members that are with you during the visit, knowledge you got during the visit, and your feedback about the visit.

Travel details

This part of your report includes technical and statistical details;

- Names of the people or students who are with you during the visit

- The place where you stayed

Feedback from students or employees

In the end, the students or employees have to provide their generalized opinion of the whole event. State whether it was useful and whether you got any specific new knowledge and experiences from it.

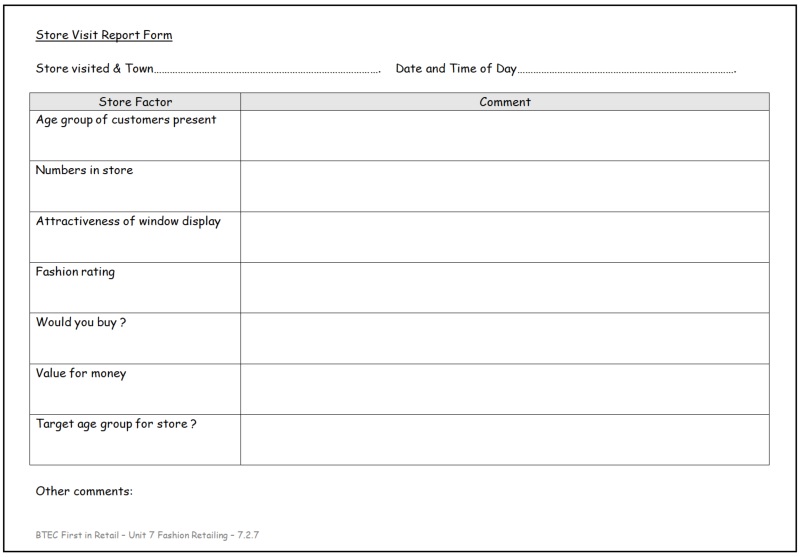

Store Visit Report Form

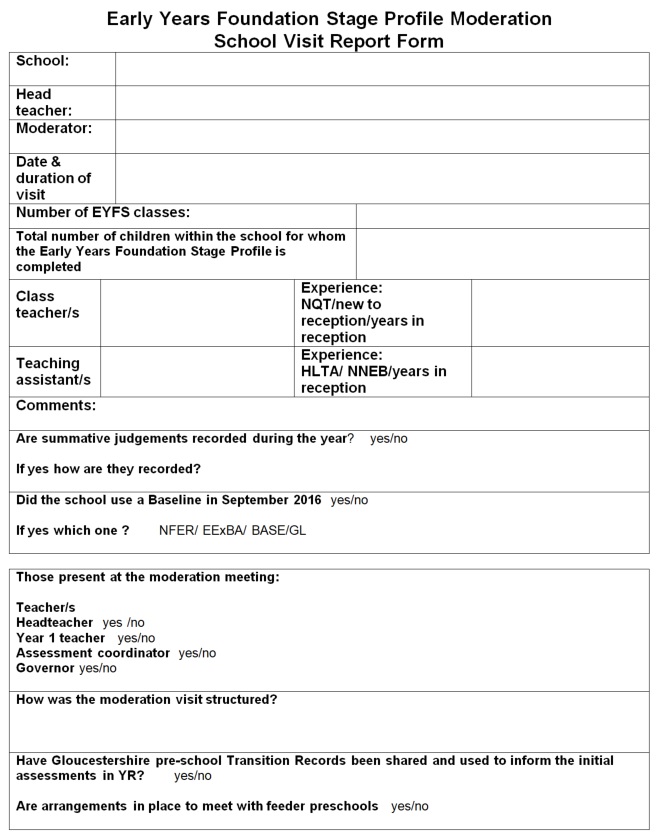

School Visit Report Form

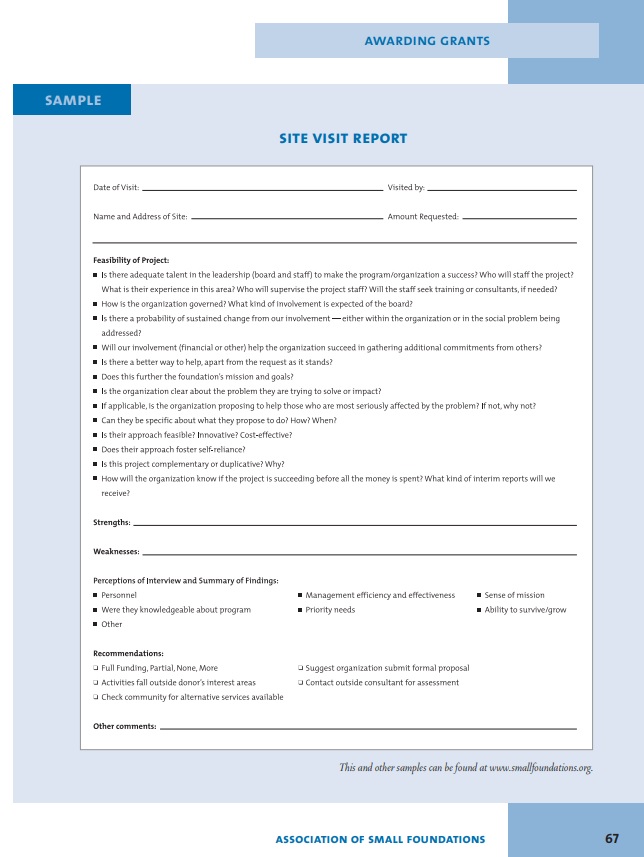

Site Visit Report Sample

Industry Visit Report Template

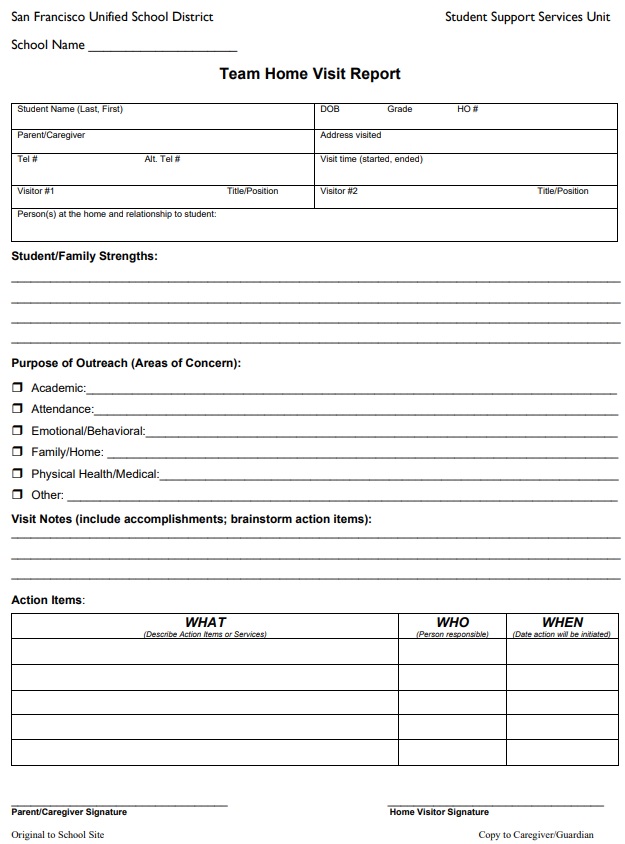

Team Home Visit Report Template

Field Visit Report Template

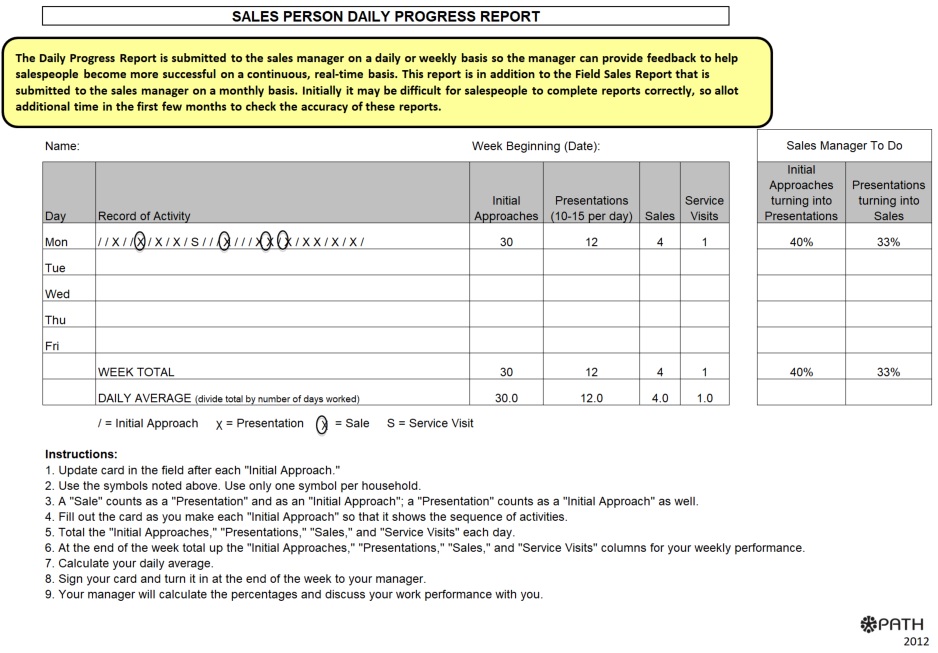

Sales Person Daily Progress Report Template

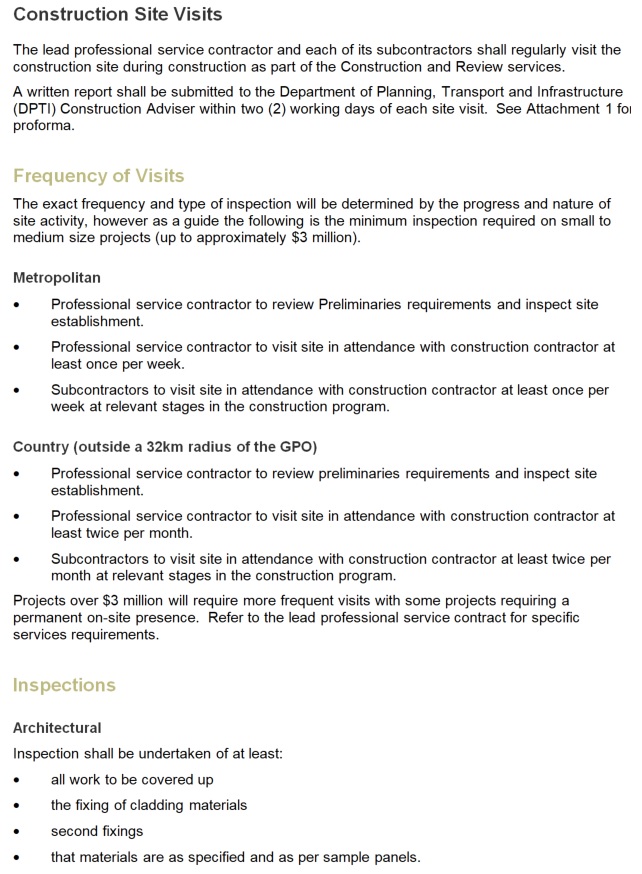

Construction Site Visit Report Template

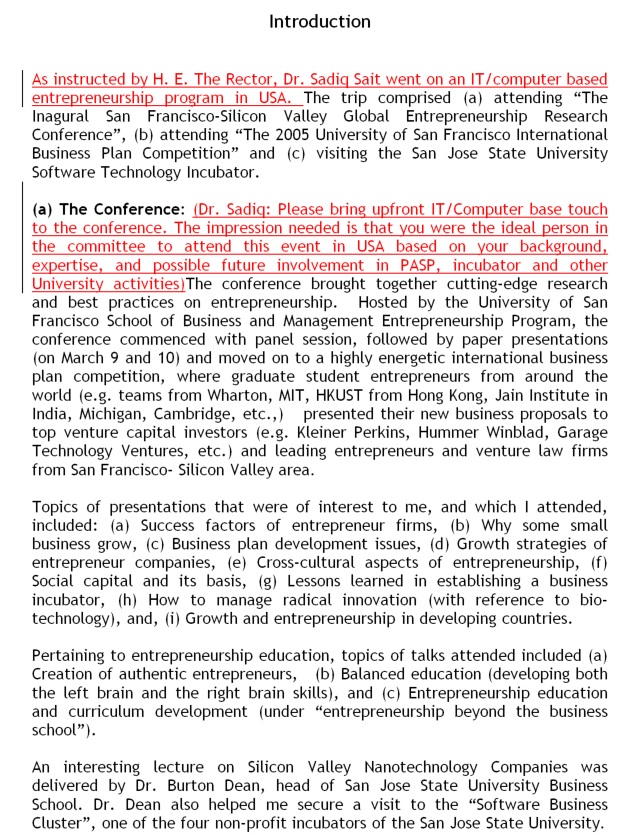

Business Visit Report Template

It provides you with updated details regarding the current events after a visit. It facilitates decision-making in a company.

First, state the general information about the visit and specify the purpose of the visit. Describe the entire visit in detail and summarize the report with important information.

You May also Like

Sharing is caring!

I am Ryan Duffy and legal writer. I received a bachelor of business administration (BBA) degree from London Business School. I have 8+ years of writing experience in the different template fields and working with ExcelTMP.com for 7 years. I work with a team of writers and business and legal professionals to provide you with the best templates.

Industrial Visit Report on Tisser India Pvt. Ltd.

Report objective: To visit textile industry and gather information about production process and working of the industry.

Fig 1. At Tisser India with Fatima Nalwala ( Sales Superviser)

Tisser Artisan Trust is a social enterprise that works to improve the lives of people in India’s rural areas. Women in rural clusters are being retrained and given career possibilities, restoring the dignity of labour. The chances generated are aimed at restoring handcraft goods inspired by India’s rich cultural past, with each art group throughout the globe having its own distinct offering. Women and art are being promoted in great steps of empowerment and exposure. The Tisser Artisan Trust is funded by the income from various grants and the commissions from initiatives we carry out in the interest of providing livelihood for artisans and reviving art. In order to keep artisans in rural clusters afloat, they are taught to manufacture things that are in high demand. It also includes quality assurance and reproduction. They will be able to work independently in the future thanks to the training and direction of cluster managers. Such financial and moral assistance aids people in escaping loan and debt traps. Tisser Artisan Trust actively promotes women’s empowerment by connecting them to larger, more inclusive value chains. The TAT team documents the lives and efforts of such empowered women.

Madhubani, Warli, Kalamkari, Ikat, Teracotta, Pattachitra, Tussar Silk, Block Print, Chanderi, Maheshwari, Dokra, and a variety of other tribal art forms are among the art forms they pursue. Campaigns like “Har Ghar Mein India,” the Grassroot Artisan Movement, and cluster development collaborations with UNDP, L&T, Pidilite, and the Maharashtra State Innovation Society helped them grow the plurality.

Fig 2. Tisser India display room

It documents the diverse stories of women and their strength, creates quality checks to maintain uniformity, builds financial infrastructures to prevent women from falling into debt traps, builds artisan clusters from a tourism perspective to open opportunities for our artisans, and helps artisans at each stage so that they can function independently, all with the goal of sustaining the community. In terms of community development, it aims to provide better opportunities for women who do not have access to education and inclusion, intervene in the value chain with small producers to encourage participation in mainstream markets, and train them in design and function to meet the market’s growing and changing demands.

They have won several awards and recognition such as Priyadarshini Award for outstanding Women Entrepreneurs, Impact award at NAFW, Seattle 2019, Rani Laxmi Bai Bhushan Puraskar, Times She UnLTD. Entrepreneur Awards 2019, Nari Shakti Awards 2018 – Business and Enterprenuership, Iprenuer – National finalist and many others.

Fig 3. Tisser India hall of fame

Tisser brand has been developed with a sense of duty in order for the loom and craft industry to remain not only a bulwark of our historical inheritance, but also to turn into an enterprising fortune of craftsmen in addition to current trade and future commerce. Tisser products are organic, handcrafted, modern, and inexpensive.

They offer wide range of handicraft products such as coasters, jewelry, books, etc

Fig 4. Tisser India handicraft products

They also have amazing collection of Apparel products for both men and women wear. These products are made by the clusters and sold across countries. These products have traditional touch of Indian art. The ir art include hand block print, tussar silk weaving, etc

Fig 5. Tisser India Apparel products

The firm has inhouse team of packaging and production department which are very keen and skilled in their work.

Fig 6. Tisser India manufacturing department

Report Summary

This visit was one of its kind to get practical exposure and deep understanding about Tisser India textiles and handicraft. Women in rural clusters are being retrained and given career possibilities, restoring the dignity of labour. Tisser Artisan Trust actively promotes women’s empowerment by connecting them to larger, more inclusive value chains. The TAT team documents the lives and efforts of such empowered women. It documents the diverse stories of women and their strength, creates quality checks to maintain uniformity, builds financial infrastructures to prevent women from falling into debt traps, builds artisan clusters from a tourism perspective to open opportunities for our artisans, and helps artisans at each stage so that they can function independently, all with the goal of sustaining the community.

In terms of community development, it aims to provide better opportunities for women who do not have access to education and inclusion, intervene in the value chain with small producers to encourage participation in mainstream markets, and train them in design and function to meet the market’s growing and changing demands. They have inhouse team of designers, web developer, graphic designer, tailors who collectively bring the community together by sharing and uplifting the art form of India through their products. This venture is one of its kind as its concept design, products and presentation skills sets it apart from others.

- https://tisserindia.com/

- https://tisser.in/

- https://www.instagram.com/tisserindia/?hl=en

By Ayman Satopay

Related Posts

Messe Frankfurt launches seven brand events in Central Asia

LANXESS at the All China Leather Exhibition, September 3–5, 2019, Shanghai, China, hall E2, stand E2-E03

TE Connectivity expands BUCHANAN PCB Connector portfolio with push-in clamp termination style

India V-Shaped Economic Recovery (GDP) : Finance Ministry

IMAGES

COMMENTS

Industrial textile mill visit is one the important element of professional education especially for textile engineering education. By mill visit students can learn about textile factories and mills, the production cycle, and the roles of textile workers.

The document provides details about an industrial visit conducted by students to various textile companies in India. It discusses three companies visited - Vardhman Group, LS Industries Ltd., and Winsome Dyeing.

This document provides an industrial visit report submitted by a 3rd year mechanical engineering student to their college. It summarizes the processes involved in silk weaving at the Mysore Silk Factory located in Bangalore.

When an individual visits the industry whether he or she is a student or an employee, they need an industry visit report template to create a visit report. This document contains a detailed summary of the visit organized in a sequence.

The document summarizes a student's industrial visit report submitted to the National Institute of Textile Engineering & Research (NITER) regarding a visit to XYZ Spinning Ltd. The report includes an acknowledgement, factory profile, objectives of the visit, description of processes and machinery observed, quality control processes, and a ...

graciously granted the opportunity to embark on a visit to Akij Textile Mills Ltd. (ATML), a renowned textile manufacturing enterprise situated in the esteemed locale of Manikgonj, Bangladesh.

Industry visit report format in PDF provides information on the data, which a person accumulates during their visit to a particular industry. It highlights how the structure of the report should be like when following the pattern for report writing.

Women in rural clusters are being retrained and given career possibilities, restoring the dignity of labour. Tisser Artisan Trust actively promotes women’s empowerment by connecting them to larger, more inclusive value chains. The TAT team documents the lives and efforts of such empowered women.

(Date of visit: 14th March 2022) The department of Electronics and Telecommunication Engineering, Prof Ram Meghe College of Engineering and Management, Badnera organized Educational/Industrial visit to Raymond Textiles, Amravati on 14th March 2022 for Third Year and Final Year students.

The purpose of the textile division is to become the chosen supplier of high-quality Bangladeshi fabric and clothes with advanced technologies and a focus on training the local workforce.