- Forklift Safety Tips

When Driving A Forklift The Forks Should Be At What Height?

When you're driving a forklift and not carrying anything, you should keep the forks about 6 to 8 inches off the ground.

It's like keeping a basketball just high enough so it doesn't roll away but low enough so you can grab it easily. This way, you won't trip anyone or hit anything lying on the floor. Imagine it as cruising on a skateboard, where you're keeping it smooth and steady, just skimming above the ground without touching it.

When you're dealing with a forklift on a slope or when it's parked, managing the height and position of the forks is crucial for safety and stability. Here's how you should handle it, with specific heights in mind:

When you're driving a forklift on a slope, the height and tilt of your forks can make a big difference in how securely you can transport the load.

- Going Uphill: If you're moving uphill with the load in front, keep the forks slightly lowered but ensure they are high enough (around 6 to 8 inches off the ground) to prevent the load from sliding back towards you. The idea is to keep the forks tilted back to secure the load, but not so high that you lose stability.

- Going Downhill: If you're heading downhill and the load is permitted to be in front, again keep the forks low to maintain stability, around the same 6 to 8 inches off the ground, and tilt them back slightly to secure the load. If driving in reverse (which is recommended downhill if the load blocks your view), ensure the load is kept uphill from you, maintaining the same height for stability.

When Parked:

- Once you've found a safe spot to park the forklift, lower the forks until they are completely resting on the ground. There shouldn't be any gap between the forks and the floor; they should be flat against the ground. This ensures that they won't pose a tripping hazard or obstruct any paths. It's not just about lowering them a bit; it's about making sure they're all the way down.

In both situations, adjusting the fork height carefully is key. On slopes, the aim is to balance the forklift and load securely, considering both the incline and the need to prevent the load from shifting. When parked, fully lowering the forks to the ground minimizes risks and keeps walkways clear. It's all about applying practical safety measures tailored to the specific challenges of each scenario.

Ready to Rev Up Your Career With Forklift Certification?

Get Certified Online & Be Job-Ready Today! It's Fast & Easy! With our online course, getting certified is as easy as clicking, learning, and succeeding. Don't let another day go by without taking the next step in your career.

When Can Carrying a Load, It is Good Practice To:

- When traveling with a load, always make sure to tilt the mast of the forklift backward so that the load will firmly place against the backrest to make it more secure during transport. By doing this, you move the center of gravity towards to rear of the forklift making it more secure when traveling.

- Distribute the weight of the load properly. If the load is off-center, it can cause the forklift to flip over. Place the heaviest load near the truck’s front wheels. Never overload, see the forklift’s load capacity in the data plate .

- Travel in reverse if the load that you are carrying blocks the front view. Don’t look at just the mirror when reversing, rotate your head and look to the path where the forklift will be going.

- Be attentive and know the height of the mast and overhead guard when traveling, especially when you are entering or exiting warehouse entrances.

- Never overload, check the maximum load capacity of the truck that you are using. Overloading causes tip over and tip-overs are frequent occurrences in the workplace and it is among the leading causes of deaths and severe injury to the operator.

- Observe the maximum traveling speed in the workplace. The permissible speed is 8 miles/hour in a typical environment but in a workplace where there is too much foot traffic and pedestrians, the minimum speed is 3 miles/hour. You can consult your safety supervisor what’s the minimum traveling speed limit in your work area.

- I put it the last, but it should be the first, never operate a forklift is you are not trained to do so. You must be certified driving the forklift .

Importance of Proper Fork Height

The proper height of the forks on a forklift is a crucial factor in ensuring safe and efficient operations. Maintaining the correct fork height helps to prevent accidents, increase productivity, and reduce damage to the load and the forklift.

One of the main reasons for proper fork height is safety. When the forks are set too high, it can cause the forklift to tip over, putting the operator and anyone nearby at risk. On the other hand, setting the forks too low can result in damage to the load or the forklift, as well as reducing the stability of the machine. Proper fork height helps to prevent these types of accidents, making operations safer for everyone involved.

In addition to safety, proper fork height is also important for efficiency. When the forks are set to the correct height, the operator can easily pick up and transport loads without having to adjust the height frequently. This saves time and increases productivity, helping to improve overall efficiency in the workplace.

Another benefit of proper fork height is damage prevention. Setting the forks to the correct height helps to prevent damage to the load and the forklift. For example, if the forks are set too high, the load may slide off, causing damage to both the load and the forklift. On the other hand, if the forks are set too low, they may hit the ground, causing damage to the forks and other components of the forklift.

Recommended Height of the Forks When Operating the Vehicle

The recommended height for the forks on a forklift depends on a number of factors, including the type of load being transported and the height of the racking or storage system. In general, it is recommended to keep the forks as low as possible while still allowing for clearance between the load and the ground. This helps to improve stability and reduce the risk of tipping.

The recommended height also depends on the type of forklift being used. For example, a reach truck may have a different recommended height than a standard counterbalance forklift. It is important to consult the manufacturer's specifications and guidelines to determine the correct height for your specific forklift.

In some cases, the recommended height may be indicated by the load itself. For example, pallets often have markings or notches that indicate the ideal height for the forks. In these cases, the operator should follow the guidelines indicated on the load to ensure proper and safe transport.

The recommended height for the forks on a forklift will vary depending on the specific circumstances, but operators should always strive to maintain a safe and stable height that allows for efficient and damage-free transport of loads.

Adjusting Fork Height for Different Situations

Imagine you're playing one of those claw arcade games, trying to grab a prize. You've got to move the claw up and down to get it just right. Driving a forklift and adjusting the forks is kind of like that, but instead of winning a stuffed animal, you're moving heavy stuff safely.

When You're Loading Stuff:

Let's say you've got a pallet you need to pick up. You don't want to just jab the forks in there; you've got to line them up nice and smooth. Here's how you do it: First, you move the forks so they're just a bit lower than the pallet. Then, you drive forward slowly until the forks are all the way in. After that, you lift the pallet just enough so it's off the ground. Not too high, though—you don't want your load to tip over. It's like sneaking a slice of pie; you've got to do it just right.

When You're Parking the Forklift:

Now, think about when you're done using the forklift, and it's time to park it. You wouldn't leave the forks sticking out; someone could trip over them, or worse. So, what you do is lower the forks all the way down to the ground. It's like putting your toys away when you're done playing. This way, the forklift is neat and tidy, and nobody's going to stumble over anything.

Getting the hang of adjusting the fork height is super important. It's all about keeping things safe and making sure you can pick up and move stuff without any hiccups. Just like getting better at a video game, the more you practice, the better you'll get at it.

Legal and Training Considerations

When it comes to driving a forklift, there's more to it than just moving stuff around. It's kind of like driving a car; you've got to know the rules of the road. But with forklifts, the "road" is usually inside a warehouse or a job site. Different places have different rules you need to follow. It's super important to know these rules inside out to keep everyone safe and avoid getting into trouble.

Think of it like playing a new video game. You wouldn't just jump in without knowing the controls or how to beat the levels, right? It's the same with forklifts. Before you start driving one, getting the right training and a special license, kind of like a driver's license but for forklifts, is a must. This isn't just to tick a box; it's about making sure you and everyone around you stay safe. Plus, knowing all the ins and outs of forklift driving can make you feel more confident and make your job easier.

So, just like you wouldn't drive a car without a license, you shouldn't drive a forklift without the proper training and certification. It's all about playing it safe and smart.

Safety Considerations

When it comes to the height of the forks on a forklift, safety should always be the top consideration. Some of the key safety considerations to keep in mind include:

- Stability: Maintaining the correct fork height can help to improve stability and reduce the risk of tipping. When the forks are too high, the center of gravity of the load can shift, making the forklift less stable.

- Visibility: The operator should always have a clear line of sight to the load and the surrounding area. If the forks are too high, the operator may be unable to see what is in front of them, which can increase the risk of accidents.

- Clearance: The forks should be high enough to clear any obstacles in the path of the forklift, such as pipes, ductwork, or other equipment. However, they should not be so high that they are likely to hit overhead obstacles.

- Load damage: Keeping the forks at the correct height can help to prevent damage to the load, such as crushing or deformation. This can help to reduce the risk of product damage and improve productivity.

By considering these safety considerations, forklift operators can help to ensure that they are using the forklift safely and efficiently, while reducing the risk of accidents and damage to the load.

So, when you're driving a forklift and not carrying anything, think of keeping the forks about as high off the ground as a couple of stacked DVD cases, roughly 6 to 8 inches. This sweet spot is like the Goldilocks zone—not too high, not too low—just right for cruising around safely.

It helps you steer clear of tripping anyone or bumping into stuff. Remember, it’s all about keeping things safe for you and everyone around, kind of like riding a bike with training wheels until you're ready to load up and lift. Keep it low, keep it safe, and you'll be good to roll.

Get Certified Fast Take Forklift Training Online

Get Started Here

Helpful Resources

- How Much Does the License Cost

- What Requirements You Need

- How to Get Certified

- Training Videos

Select Your State:

- Connecticut

- Massachusetts

- Mississippi

- New Hampshire

- North Carolina

- North Dakota

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- West Virginia

- Donate to Us

- Privacy Policy

- Cookie Declaratrion

Employer Beware

- How Do I Find Cost Effective Forklift Training for My Forklift Operators

- Why On-Site Forklift Training is Your Best Choice

- Forklift Train The Trainer

- Forklift Certification Card: Info to Include in the License Template

- Will the Company Train Operators to Drive Forklifts?

- How Was Operator Being Trained to Become OSHA Certified

- Goal of Effective Lift Truck Safety Training

- Requirements of Forklift Safety Training

- Is Vision or Hearing Impairment Prevents an Individual From Operating Forklifts?

- Do employers need to provide forklift training for each make and model?

- Forklift Training Materials That You Should Have

- How Long Should You Retain Forklift Training Records?

Operators: Read These!

- Book a Trainer

- Search Jobs Here

- I Was Injured At Work Driving Forklift, Is My Employer Liable?

- How Much Is Your Salary (by State and City)?

- Can You Still Use Your Valid Forklift Certification to Work With Another Company?

- Can You Get a Forklift Job If You Have DUI?

- Can You Use Your Forklift Certification to Work in Other State?

- Can You Use Your Forklift License to Work In Other Country?

- How to Become Certified Forklift Operator?

- Where Can You Go To Get A Forklift License?

- How To Choose The Best Forklift Training School?

- What Requirements You Need?

- How To Pass The Forklift Practical Test?

- Passing the Training Written Test

- How Much Does It Cost You To Get Forklift License?

- How Long Does It Take To Take the Training

- How to Renew Forklift Certification?

- Is Online Forklift Certification Right For You

- When to Take Forklift Refresher Training?

- Important Areas Being Evaluated During Hands-On Driving

- How Forklift Operator Become OSHA Certified?

- How Much Are Your Fines and Penalties For Not Getting Certified?

- What Are The Forklift Operator Qualifications?

- What Are Your Job Descriptions?

- What to Do If You Lost Your Forklift License?

- Steps to Get Forklift Training [Infographics]

- Forklift Classes

- Can I retry if I fail forklift certification Test?

- Where Can I Learn How To Drive A Forklift?

Want to Save Money? Certify Your Own Operators! Use This:

Connection:

Your most practical material handling solution provider

What is the proper way to load/unload and travel in a forklift with load.

Engaged in forklift industry since 2009

As a Forklift Operator, there are a few essential things to remember when operating the forklift, especially when in transit or loading and unloading. Here, we will discuss all safety precautions to practice for specific activities.

Ensuring safety in the workplace and eliminating potential injuries to the people in the workplace is the first thing to keep in mind when doing loading and unloading operations.

Loading the Forklift

- Always wear your seat belt.

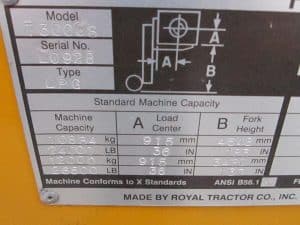

- Remember your training- pay attention to the nameplate on the forklift to be aware of the forklift’s rated capacity.

- Use the appropriate lift fixture for the type of load.

- Keep the load stable and centered by proper placement, uneven or loose loads tied, and forks as wide as possible.

- Insert the forks carefully and securely into the pallet. Make sure you don’t damage the materials stacked next to it.

- Drive under the load until it touches the carriage. Tilt the forks back to shift the weight and make it more stable.Keep the heavier end closer to you and tilt the mast back to prevent an unbalanced load.

- Keep it titled before you drive the forklift.

Driving the Forklift with Load

After loading your truck, the next thing is to transport the load to its destination. Driving the forklift to whatever distance is as risky as loading it and appropriate safety rules must also be followed.

- Avoid potential hazards from falling by keeping your forks 6 to 10 inches above the ground.

- Keep in mind that forklifts are top-heavy that loads must be carried low and the mast tilted back.

- Driving on an uneven floor/road can potentially tip your truck over. Drive with caution.

- Placing anything on the overhead guard is not advisable.

- Visual is important. Travel in reverse if something is blocking your front view and always look in the direction you’re traveling. In challenging situations, you can use a spotter to help you.

- Keep your arms and legs inside the forklift. Reaching out through the mast to adjust the load is very unsafe and can cause injury.

- Maintain the position of your forks while moving. Never make it lower or higher while in transit.

- Know when to adjust your driving and speed according to the floor surface and weather conditions.

- Make sure your speed is appropriate when moving but when stopping as well.

Unloading the Forklift

While loading the truck might seem similar to unloading it, unloading comes with safety protocols that operators must follow.

●Unloading in Truck/Trailer

- Before unloading, ensuring the correct positioning of the forklift and forks is crucial.

- When unloading in a truck/trailer, check the inside to make sure the bed is in good condition and the height is appropriate for the unloading to avoid issues or mishandling of the load.

- Another thing to ensure is that the truck/trailer will not move during the unloading process. Make sure the brake is locked, chock the wheels and the dock plate is down and secure.

- Drive in slowly while positioning the load. Tilt the forks forward until it is at the same level as the unloading bed.

- Lower the load gently and release.

●Unloading onto Stack

- Make sure you get cleared for the overhead before raising the load.

- Raise and position the load to the correct height with 2 inches allowance above the stack and 2-3 inches on the side and back of the load

- Slowly move the load into position. Tilt the load forward, lower it and make sure the forks are no longer tilted before slowly releasing then pull the forks slowly.

After unloading, the following should be followed:

- Check if you’re clear to reverse before doing so. Wait for the backup alarm to sound before slowly backing up.

- Make sure your vision is clear before moving the forklift.

- Stop the forklift and lower the forks, as low as possible, at least 2 to 5 inches above the floor. On uneven terrains, the height should be able to accommodate the uneven ground.

FORKFOCUS, is a professional forklift supplier. Count on us to get a safe and reliable forklift! Free forklift service or pre-consulation is always available. Contact our forklift expert for now!

***Warm warn Prompt : Pls feel free to comment below and pls on worry that we won’t and would never publish your mail address or send any marketing mails to you without your consent.

Stay in Touch

Subscribe newsleter for free and become the insider with us.

- IC Forklift

- Electric Forklift

- Reach Truck

- Pallet Truck

- Aerial Lift Platform

- Electric Tow Tractor

- Forklift Attachment

- Spare parts for forklift

- 360 Forklift Service

- Additional Value

- Customer Center

- Factory Overview

- Download Center

- 24 hours call: 008613867191752

- Xiamen Mhepro I-equipment Co.,ltd

- No.31 pingshan Nanli, Haicang District, Xiamen City, Fujian, China

"WALKS STEADY TO MAINTAIN A SUSTAINABLE GROWTH" --fORK FOCUS team.

Copyright © content is reserved by forkfocus, ask for a quick quote.

We will contact you within 8 hours. please pay attention to the email with the suffix “@forkfocus.com” .

- Skip to primary navigation

- Skip to main content

- Skip to primary sidebar

Forklift News

Forklift news, updated daily

How High Should a Load Be Carried on a Forklift?

May 11, 2024 By Faisal Ur Rehman

Knowing how high to carry a load on a forklift is vital for material handlers. Ensuring operational safety in forklift use involves careful attention to fork positioning and the height at which loads are carried. Maintaining the correct load height is crucial for safe material handling operations, including maintaining stability, operator line of site and load stability.

- 1.1 Enhanced Stability

- 1.2 Improved Visibility

- 1.3 Load Security

- 2 Key Considerations for Safe Forklift Operation

The Importance of Keeping Loads Low

When operating a forklift, keeping the load low to the ground is essential, typically between 4 to 6 inches above the floor. This positioning offers several critical benefits. Keeping the load low maintains a lower center of gravity, significantly enhancing the forklift’s stability. This minimizes the risk of tipping, especially when navigating turns or uneven surfaces. A higher load raises the center of gravity, making the forklift more prone to tip over. Keeping the load low helps keep the center of gravity within the stability triangle of the forklift, preventing dangerous tip-overs.

Enhanced Stability

One primary reason for maintaining a low load height is to ensure the forklift’s stability. As the load is raised, the center of gravity shifts upwards and forwards, which can destabilize the forklift. If the center of gravity moves outside the stability triangle, the forklift is at a higher risk of tipping over. By keeping the load low, the center of gravity remains stable, thereby reducing the risk of accidents.

The center of gravity plays a crucial role in the stability of a forklift. When the load is low, the center of gravity is closer to the ground and within the stability triangle, making the forklift more stable. A higher load shifts the center of gravity upwards, making the forklift top-heavy and more susceptible to tipping, especially when making turns or driving on uneven surfaces.

Tip-overs are a significant risk when operating forklifts. A high load increases this risk by raising the center of gravity. Keeping the load low helps maintain the center of gravity within safe limits, preventing the forklift from tipping over during operations. This practice is crucial for both the safety of the operator and the surrounding workers.

Improved Visibility

A low load position allows the operator to see over the load, ensuring better visibility of the path ahead and reducing the risk of collisions with obstacles, other vehicles, or pedestrians. When carrying large or bulky loads obstructing the operator’s view, it is advisable to travel in reverse to maintain a clear line of sight, except when moving up an incline. Maintaining forward visibility is essential for safe forklift operation. By keeping the load low, operators can see the path ahead more clearly, avoiding obstacles and ensuring safe navigation. This practice is particularly important in busy work environments with high collision risk. Having the load in a low position also makes it easier for the operator to assess load clearance from obstructions than when the load is elevated.

Large or bulky loads can obstruct the operator’s view, increasing the risk of accidents. In such cases, traveling in reverse can help maintain visibility. Additionally, using mirrors and regularly checking clearances can further enhance the operator’s awareness of their surroundings, contributing to safer operations.

Load Security

Keeping the load low reduces the chance of the load shifting or falling during transit. A lower load position also ensures that the load remains securely against the backrest, providing additional stability. Proper load handling includes ensuring the forks are tilted slightly back to secure the load against the backrest and checking for adequate overhead clearance before lifting the load to avoid collisions with overhead structures like lights, pipes, and sprinkler systems.

A low load position minimizes the risk of the load shifting during transit. Load shifts can destabilize the forklift, leading to accidents. Operators can prevent such incidents by keeping the load low and secure against the backrest, ensuring safer and more stable operations. Operators should always check for adequate overhead clearance before lifting the load. Collisions with overhead structures can cause damage and pose significant safety risks. Maintaining a low load height helps avoid such collisions, contributing to safer operations.

Carrying the load 4 to 6 inches above the ground helps avoid ground-level obstacles such as bumps, debris, and dock plates. It also prevents collisions with infrastructure and other objects in the operating area. Proper load handling includes ensuring the forks are tilted slightly back to secure the load against the backrest and checking for adequate overhead clearance before lifting the load to avoid collisions with overhead structures like lights, pipes, and sprinkler systems.

Key Considerations for Safe Forklift Operation

Ensuring that the load is balanced and secure before lifting is essential. Approach stacks or racks straight on, lift smoothly, and avoid jerky movements. When placing a load, lift it above the lower stack, tilt the mast slightly back, and ensure the load does not catch on obstructions. A properly balanced and secure load is less likely to shift or fall during transit. Verifying the load’s balance and securing it correctly can prevent accidents and ensure stable operations. When placing a load, it is important to lift it carefully, ensuring it is clear of obstructions. Properly positioning the load before lowering it can prevent damage and ensure safe operations.

Operators should continuously monitor clearances and surroundings to maintain awareness and prevent accidents. Utilize mirrors to improve visibility around the forklift. Regularly checking clearances can help prevent collisions and ensure safe navigation. Operators must undergo thorough training, including formal instruction and practical exercises, as mandated by OSHA. Continuous supervision ensures operators adhere to safety protocols and helps identify areas needing further training. Comprehensive training and effective supervision are essential to fostering a workplace safety and compliance culture.

Maintaining the correct load height and ensuring clear visibility are fundamental practices for safe forklift operation. By keeping loads low to the ground, operators can enhance stability, improve visibility, and avoid obstacles, thereby minimizing risks and improving overall safety. When handling long loads and navigating narrow spaces, consider using side loaders or multi-directional forklifts to reduce risk, as demonstrated in this video . By adhering to these guidelines, forklift operators can ensure safer and more efficient material handling in various industrial settings.

Disclaimer: The information provided in this article is for general guidance only and should not be construed as professional advice. Forklift operators should always follow the specific safety protocols and operational procedures established by their employers and adhere to all applicable local, state, and federal regulations. The practices recommended here are intended to supplement, not replace, the guidelines and requirements set forth by regulatory bodies and organizational policies. Always consult your supervisor or a safety professional if you are unsure about any aspect of forklift operation.

Faisal Ur Rehman is the content editor of ForkliftRevolution.net and Search Engine Optimization Team Lead for Carrollton, Texas-based Blue Box Packaging .

About Faisal Ur Rehman

Size Matters—A Refresher on Critical Forklift Dimensions

Critical forklift dimensions to know before heading out….

…not only in height, but also length and width.

We’ve all heard about those unfortunate incidents of trucks driving on car-only parkways and having an untimely meeting with an overpass. Ouch! You need to be aware of the same thing happening to you and your forklift. Alternatively, you don’t want to find your forklift wedged into an aisle where it can’t move.

All forklifts were not created equal. Different forklifts have different dimensional limitations, and forklift operators need to be thoroughly aware of those limitations, especially if you’re using more than one type or brand of forklift. Always remember safety first!

Here’s a rundown of the important forklift measurements to help you avoid knocking off a sprinkler head or getting jammed up in a too-narrow aisle.

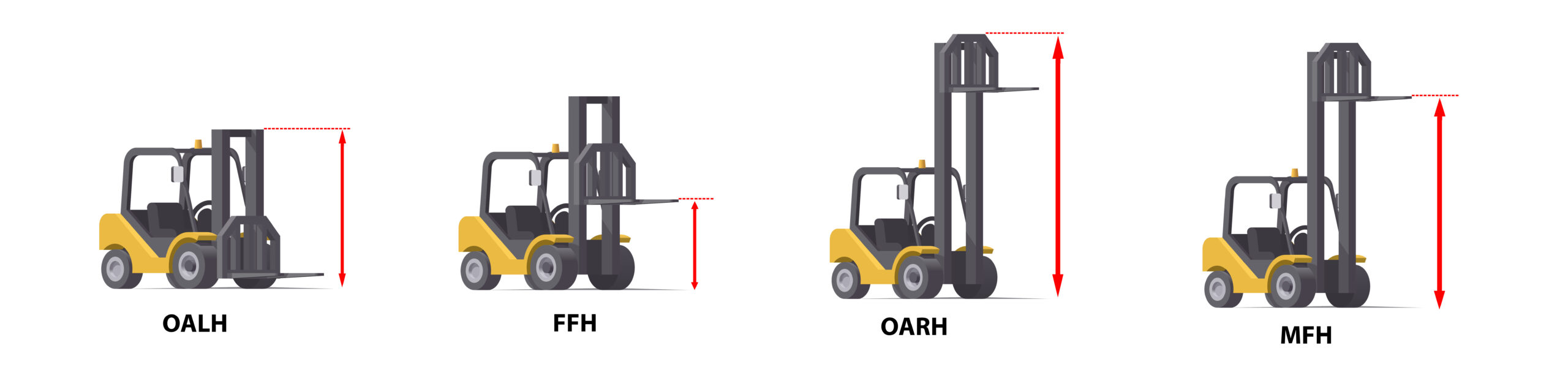

- Overall Lowered Height (OALH) This is the height of the forklift mast with the forks in their lowermost position. This is important to know for cruising around the warehouse or driving into a trailer on the dock for loading or unloading. Be aware of ceiling fixtures like sprinklers, lights, hanging ventilation units, fans and electrical conduits. Sometimes they’re lower than they seem. Use caution when driving through rack tunnels.

- Overall Raised Height (OARH) When the mast is fully extended, this is the dimension from the floor to the top of the mast. It’s important to know this height—especially if your warehouse has multi-tiered racks. Again, be cognizant of utilities and HVAC units mounted on the ceiling. You don’t want your mast to go crashing into the overhead lights when you’re picking up that pallet from the highest rack.

- Free Fork Height. (FFH) This forklift measurement is the height of the forks from the floor when they are raised to a position before the mast starts to extend. FFH is important to know when your headroom is limited, like unloading a double-stacked trailer truck. Or if you’re removing double-stacked pallets on the floor from a drive-in system when there are pallets on rails stored above you. Otherwise…look out below.

- Maximum Fork Height (MFH) You’ve made it to the top! MFH is the highest position the forks can achieve. While this seems like an obvious dimension, it needs to be taken into account, especially in a warehouse that has racking of different heights. Don’t forget that MFH has to be at least 8 in. higher than the level of the highest pallet to allow for lifting the pallet before storage or removal.

Note – The forklift’s rated load capacity is based on weight distribution as much as it is with load weight and size. The intent is for loads to be centered with the weight evenly distributed across the forks. Irregularly shaped, unbalanced, or loads not placed at the back of the forks may cause you to exceed the rated load capacity found on the forklift’s data plate. To learn more about choosing the right forks for the job, check out our blog: Forklift Forks – A Two Pronged Approach to Selection & Maintenance

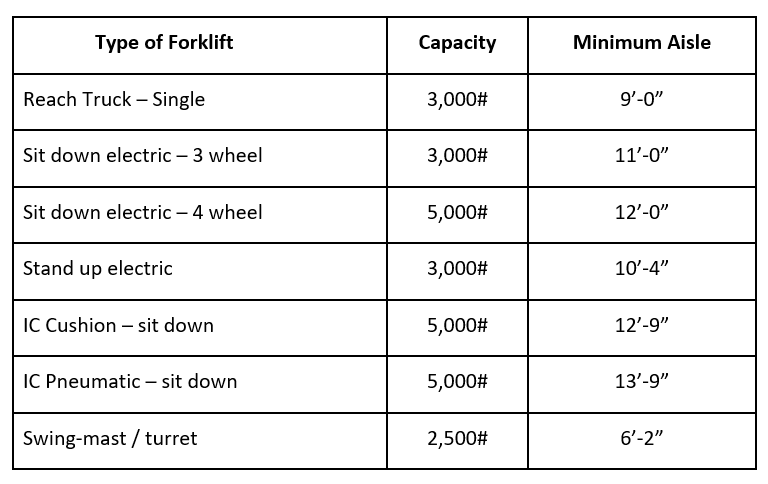

Forklift Dimensions – The Wedge Effect

Vertical forklift measurements are not the only ones that must be taken into account when operating a forklift. We all know that experience of having your parked car wedged in by a guy who squeezes right up to your bumper – not good. Or, trying to maneuver past the double-parked delivery truck on a narrow street.

To a great degree, aisle width determines the length dimension of the forklifts you can use in your warehouse. Some facilities are designed for standard pallet rack with wider aisles, while others plan for very dense storage with very narrow aisles. Here are the forklift dimensions for choosing a forklift at an existing warehouse.

Your Go-To Forklift Length Measurements

- Head Length – This is the length of your forklift from the back of the truck to the front of the load backrest.

- Load length – The length of the pallet along the stringer plus any product overhang

- Overall Length (OAL) – This is the sum of the above two dimensions.

- Right Angle Stack Length – This forklift measurement is the smallest space within which a forklift can make a 90° turn and is similar to head length.

To calculate minimum rack-to-rack aisle width for a forklift, use the formula:

Right Angle Stack Length + Load Length + 12 in. (for maneuverability) + 6 in. (for pallet overhang)

Aisle Widths – Rules of Thumb for Different Forklift Types

Generally, a sit-down, counterbalanced forklift requires a wide aisle of 11 to 14 ft. A stand-up counterbalanced forklift can fit into a tighter space, typically 11 to 12 ft. depending on the model. Warehouses designed with narrow aisles, say 9 ft. wide, require the use of a reach truck to safely clear the aisles and load and unload pallets. For very narrow aisles, those that are less than 9 feet, a swing-reach or turret truck must be used. These are usually accompanied by a forklift guidance system.

Width is also an important forklift dimension to consider, especially if your forklift is equipped with outriggers to increase stability. This is an especially important measurement in drive-in rack setups.

Note that all the above forklift dimensions are just guidelines. Actual measurements of aisle widths and forklift dimensions should be made to ensure maximum productivity and safety. Use of attachments also changes all the above assumptions, since these have their own sets of dimensional limitations.

Your Apex forklift application specialist is the best resource for helping you determine the right forklift for your specific application. We can provide a recommendation for the forklift that offers you the best combination of productivity, efficiency and safety. We can also provide training for new or existing workers to get them up to speed on best practices in forklift operation. Just give us a call at 833-226-4573.

The Forklift Buyers Guide

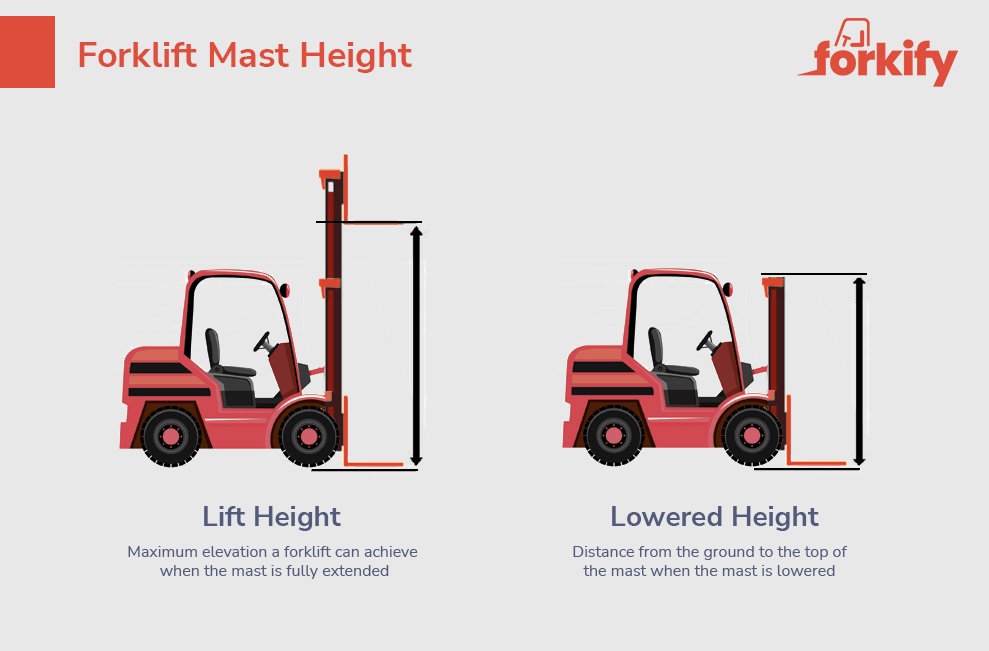

- Forklift Lift Height

The term “lift height” refers to the maximum elevation a forklift can achieve when the mast is fully extended.

Why does the lift height of a forklift matter?

Lift height is important because it determines how high a forklift can raise a load. This is crucial in various settings like warehouses, construction sites, and storage facilities where items are often stacked at significant heights.

A forklift’s lift height can impact productivity and efficiency, as it dictates whether or not the forklift can reach certain levels. It’s also vital for safety reasons, as overloading or attempting to lift beyond the forklift’s maximum lift height can lead to accidents and damage.

Calculating The Maximum Forklift Lift Height You Require

Source: forkify.com

Calculating the lift height you require for a forklift involves several steps:

Assess Your Environment: Measure the highest point that your forklift needs to reach. This could be the top shelf in your warehouse or the highest point of stacked materials.

Consider the Load Height: Keep in mind the height of the load that will be lifted. In other words, the forklift should be able to lift higher than the combined height of your tallest shelf and largest item.

Factor in Safety Clearance: Add a safety margin to allow for safe manoeuvring of the load. This is typically around 5-6 inches but can vary depending on your specific circumstances.

Account for the Forklift’s Maximum Load Capacity: Remember that a forklift’s maximum lift height may decrease as the weight of the load increases. Make sure the forklift can handle the weight of your heaviest load at your required lift height.

By taking all these factors into account, you can calculate the minimum lift height and maximum lift height you need for your forklift. It’s always a good idea to choose a forklift with a lift height slightly more than your calculation to ensure it can meet all your needs.

Consider Closed Height

The closed height, also known as the ‘lowered height’ or ‘clearance height’, refers to the minimum height of the truck when the mast is fully lowered. This measurement is taken from the floor to the highest point of the lowered mast.

Calculating the closed height is a crucial and often overlooked step, it’s essential to ensure adequate clearance between the forklift’s closed height and any doorways to ensure smooth transportation of your machine and of course safety.

The Buyers Guide

- Introduction

- Understanding The Types Of Forklifts

- Forklift Fuel Types

- Forklift Lift Capacity

- Should I Buy a New or Used Forklift?

- How Much Does a Forklift Cost?

- Forklift Financing Options

- Pre-Purchase Evaluations

- Summary & Final Thoughts

Privacy Overview

Six Measurements You Need To Understand Before Operating A Forklift

Catalogs & Resources

Technical Articles

Tire & Wheel Articles

Operations & Safety Articles

Product Spotlight Articles

Customer Spotlight Articles

Six Measurements You Need To Understand Befor…

11th Jul 2020

Forklifts come in different dimensions that are a key determinant for safe operations in different spaces.

For forklift operators/owners to pick the right forklifts for their work spaces, they need to understand the dimensions of those forklifts and figure out if they are a fit for their warehouses.

In this article, we look at some of these dimensions and why they are important to understand.

Overall Lowered Height

The Overall Lowered Height refers to the length of the forklift mast from the floor up to its top once the forks are lowered. Knowing this measurement helps you figure out if you can operate safely with adequate clearance without causing damage to doorways, low-hanging fixtures in ceilings/aisles, and semi-trucks.

Overall Raised Height

The Overall Raised Height is the length of the mast when it is fully extended with the forks achieving their maximum possible height.

Understanding this measurement will help you determine the suitability of your forklift accessing the highest placed inventory in a rack without striking fixtures on the ceilings, overhead fixtures like sprinkler systems, and the roof of trucks.

Free Fork Height

The Free Fork Height is the maximum height the forks can achieve without the extension of the mast.

Knowledge of this height is very critical to prevent damage to the racks or pallets as it helps you establish the suitability of the forklift to access the topmost placed pallets without problems.

Maximum Fork Height

The Maximum Fork Height is the highest height the forks can achieve with the mast fully extended.

If your warehouse lacks adequate clearance to accommodate a fully extended mast, it can present problems like damage to the racks and pallets since you will not be able to properly access the goods.

Overhead Guard Height

The overhead guard height is the length of the forklift from the floor to the top of the overhead guard.

Some forklifts are designed with the overhead guard height longer than the overall lowered height.

Knowledge of this height ensures you can operate the forklifts through doorways and trucks without damage.

Overall Length and Width

The overall length is the measurement of the forklift from the tip of the forklifts/attachments to the back of the forklift.

On the other hand, the overall width of the forklift is the measurement of the forklift from one side to another.

These two measurements are very important for determining the turning radius of the forklift which helps establish how long and wide your aisles should be to prevent accidents.

Therefore before you can pick a forklift, you need to understand some of its very important dimensions like the overall lowered height, overall raised height, Free fork height, Maximum fork height, Overall Guard Height, Overall Length and Width.

It is this knowledge that will help you pick a forklift that you can operate in your warehouses without any damages.

Forklift Tire Company is one of the largest suppliers of forklift tires in the USA. We are happy to help you find the right tires for your forklift truck. Visit our online store here for great discounts or email us at [email protected], our customer service team is ready to assist you.

- Our Brands Our Brands

- Cat Lift Trucks

- Mitsubishi Forklift Trucks

- UniCarriers

- Jungheinrich

- Lift Truck Solutions

- Heritage Brands

- Solutions Solutions

- Battery Solutions

- Fleet Solutions

- Material Handling

- National Accounts

- Support Support

- Operator Training

- Rental & Used Equipment

- Our Dealers

- Why Us? Why Us?

- Our History

- Customer Stories

- Manufacturing Expertise

- Preferred Partners

- News & Press

- Find Your Dealer

- Find Your Region

- Cat ® Lift Trucks

- Jungheinrich ®

- Unicarriers ®

UNITED STATES / CANADA / MEXICO

Central & south america, europe, africa & the middle east, asia, pacific & south africa.

- Unicarriers

- Resources >

- Forklift Load Capacity

Understanding Forklift Load Capacity

One of the most important elements of accident prevention is keeping a safe load capacity. We’ll explain what it is and what you need to know to stay safe.

Safety is an important topic for all forklift operators.

Just to name a few, operators must be trained on the specific forklift and in the specific work environment which includes:

- understanding the purpose and function of all features (e.g. horn, alarms, controls, etc.) of the lift truck

- being aware of any potential workplace hazards and how to avoid them

- never operating a forklift for any purpose other than its intended use

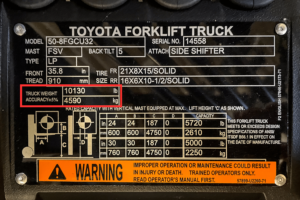

- while traveling, do so at a safe speed, look in the direction of travel, and keep the load at a lowered travel height

- always properly securing the load

- and never exceeding the rated capacity of the forklift they are operating

That last bullet point is critical. Keep reading to understand why a forklift’s load capacity is important.

What is the load capacity of a forklift?

A forklift's maximum load capacity, or weight capacity, is the maximum rated load it is allowed to lift for a given forklift and attachment configuration. The stated load capacity of a forklift only applies to the load center indicated on the load capacity data plate. If the load’s center of gravity is not centered at the specified position, the forklift's weight capacity will be reduced. Loads come in all shapes and sizes, not just symmetrical boxes.

What is the maximum weight a forklift can carry?

The maximum weight a forklift can carry depends on several factors. The load size, position and weight distribution all critically affect the forklift's load capacity and the stability of the truck. For example, if a 2,000-pound rectangular box is stood up vertically, the forklift's load capacity will be higher than if it is positioned horizontally with the long end of the box overhanging the forks.

Some forklifts may require additional counterweight be installed to help offset the weight being lifted by the forklift. This helps keep the forklift stable while it’s lifting and moving. Forklifts are designed for maximum carrying capacities using the counterweight for balance, the front wheels as the balance point and the center of the forks as a predetermined location on the forks where the load’s center of gravity needs to be located in order to achieve the maximum load capacity (i.e. load center).

Different load carrying attachments can also have an effect on a forklift's maximum load capacity. It's important to make sure that operators understand the new rated capacity of the forklift whenever a new attachment is used. In some cases, the forklift's maximum rated capacity will be decreased when a different attachment is used.

Mast height can also influence a forklift's maximum rated load capacity, as the rated capacity can be reduced at greater lift heights. Forklifts with high masts may have different capacity ratings for the different lift heights; operators should always refer to the forklift manufacturer's load capacity data plate and the Operator's Manual for mast height capacity ratings.

Risks of exceeding forklift load capacities

There are several potential hazards that can occur when a forklift exceeds its maximum load capacity. These include, but are not limited to:

- Tipping over

- Dropping the load

To avoid these risks, operators should:

- know where to find the forklift’s load capacity data plate

- understand the effects of a load’s weight, shape, size and position on a forklift's rated capacity

- minimize the distance from the front wheels to the load’s center of gravity

- load the heaviest part towards the mast

What is a forklift load capacity data plate?

All forklifts are equipped with a load capacity data plate . It is usually found in a location that the operator can see from the normal operating position or can easily access. This plate, which also may be in the form of a durable decal, goes by a variety of names including nameplate, data plate, weight plate or load plate. Depending on the forklift make and model, the plate will differ slightly and may display some or all of the following information:

- General forklift information such as: brand and model, serial number, and forklift type.

- Information on parts and components: Tire types and sizes, mast type and front tire tread.

- Forklift weight

- Battery weight

- Attachments used in determining load capacity

- Load capacity

- Maximum lift height

- Load center distances

How to avoid load capacity issues

Here are some basic rules you can follow to avoid running into forklift load capacity issues and unsafe work environments.

- Ensure operators are trained and have read and follow the instructions in the operator’s manual

- Always make sure the forklift is in proper working condition

- Never exceed the forklift’s stated load capacity on the load capacity data plate

- Buy or lease forklifts with a load capacity that’s more than what you need for the job

- Make certain that the load capacity data plate is legible and matches your specific forklift / attachment combination

- Train operators to always know the weight of the loads they are going to carry and to use the load capacity data plate – never make assumptions

- Always travel at a speed that will maintain control of the forklift and load and keep the load in the lowest position possible

Operator awareness and proper training are the best means for accident prevention. If you still have forklift load capacity questions, contact your local forklift dealer for assistance.

ADDITIONAL RESOURCES

- Forklift Safety Rules of the Road

- How to Get Forklift Certified

- Developing a Daily Forklift Inspection Checklist

- Social Media

- Privacy Policy

- Terms & Conditions

- Forced Labor Statement

© 2024 Mitsubishi Logisnext Americas Inc. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Yellow”, the “Power Edge”, and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar Inc., and may not be used without permission. All registered trademarks and all logos are the property of their respective owners, including Jungheinrich®. UniCarriers® is a registered trademark of Mitsubishi Logisnext Co., Ltd. ROCLA trade name, its respective wordmarks and logos as well as corporate and product identity used herein, are trademarks of Mitsubishi Logisnext Europe Oy, and may not be used without permission.

Let us help you find the right material handling solution for your business.

- Request Service

- 855-662-4379

Fallsway Blog

Read and explore educational information about forklifts and truck equipment, plus the latest news and events from Fallsway Equipment.

- Fallsway News

- Forklift Education

- Meet The Equipment

- Truck Equipment Education

Forklift Measurements

Before you operate a forklift, you should be aware of the crucial measurements that determine if you can perform a task safely. This blog will address the importance of knowing the measurements of the mast and forks, and how those measurements affect your operation.

First, some of the potential hazards that all forklift operators should know of:

- Striking racks, semi-trailers, and truck ceilings

- Striking lamps, ceiling fixtures, and heaters

- Falling objects

- Any other situational hazard

Next, you should be aware of the dynamic ranges of your vehicle and determine whether your forklift can safely operate in the provided space. To determine this, you must know a few measurements such as Overall Lowered Height (OALH), Overall Raised Height (OARH), Free Fork Height (FFH), and Maximum Fork Height (MFH). With this knowledge, you are able to safely determine if the forklift can get the job done and if any other steps are necessary. In the next section, we will discuss what each measurement means and any other potential hazards we are looking for.

Overall Lowered Height

Potential Hazards include: Overhead obstructions including doorways and ceiling fixtures.

Overall Lowered Height (OALH) takes into consideration any doorways, low-hanging fixtures, or low ceilings that an operator may encounter. Each operator should be aware of the height of the mast when it is lowered and how this may impact operations. You may also have to take into consideration what will happen when the forklift is inside of a truck and has to raise the forks to retrieve double-stacked pallets.

Overall Raised Height

Potential Hazards include: Roof of semi-trailer or truck, ceilings, overhead fixtures including lights and heaters.

Overall Raised Height (OARH) is the maximum extended mast height with the forks at their highest point and the clearance required with such an extension. Similar to OALH, we are concerned with any obstacles that could impede operations. This includes any overhead obstructions that could be within striking distance. When dealing with the OARH it is recommended to never travel with the load elevated or exceed the stated capacity at the highest stack heights.

Free Fork Height

Potential Hazards: Striking racking or pallets. Striking the roof of a tractor-trailer or truck.

Free Fork Height (FFH) is the height that your forks can reach without extending the mast. You can determine this height by determining the fork height required to load and clear the top pallet from a double stack while also within the confines of the truck or semi-trailer you are dealing with.

Maximum Fork Height

Potential Hazards: Striking racking or pallets, collision, falling objects.

Maximum Fork Height (MFH) is, you guessed it, the height of your highest pallet position. While this can seem obvious, it is still crucial to take an accurate measurement. If any variables are changed you could potentially be in a dangerous operation. You should always know the maximum height your forks can reach with the mast extended. Next, evaluate whether your forklift can lift the load to the highest stack with enough clearance for a safe operation.

Knowing the necessary measurements is critical to any operation. While this information may be repetitive to those of us with experience in the industry, it is critical to remember to double-check every variable when a new change is introduced. If you are interested in learning more, contact us today to speak directly with a salesperson.

- Service & Repair

- Pallet Racking

- Get A Quote

When Using a New Forklift, How Do You Calculate Its Load Capacity?

If you’re a forklift operator or a warehouse manager in charge of one, your most significant responsibility is remaining safe while operating material handling equipment. To keep you and others safe, you want to be sure that the load you are transporting on your forks does not exceed the load capacity for that machine. That’s why it’s essential to check the data plate before operating a new forklift.

Here at Sam’s Mechanical, we know that approaching a large pallet can make you uneasy, especially if you are a newer forklift operator. However, with your forklift training and help from our expert team of forklift professionals, you can confidently and safely transport any load.

For over 25 years, we have helped warehouses ensure their material handling equipment is operating safely, so you can do the job you get paid to do—and return home in the same condition you arrived at work.

Read the Forklift’s Data Plate

When you purchase a new forklift , one of the first tasks you should do is read the data plate, like the one pictured here from one of our Royal Forklifts . All forklifts must have this plate that specifies their load capacity. It will often include other information like mast height, load center, and lifting capacity of the forks alone without any attachments .

So, if the capacity of a piece of equipment is 24,000 pounds, like on the one pictured, that means you can lift any load up to that weight, right? Well, not exactly.

The capacity listed on a reach truck, lift truck, electric forklift , or another piece of machinery is based on a pallet load that is twice the length of the load center. So, in this example, this forklift can handle a pallet that is 72”x72” and weighs up to 24,000 pounds in optimal conditions.

What Are Optimal Conditions?

The key here is optimal conditions . You know you have optimal conditions when the pallet you are transporting is:

- Smaller than the maximum size listed on the data plate

- Positioned at the back of the forks

- The mast is in the upright position

- The forks are placed low to the ground

- The forklift is driven at a low speed

If any of these conditions aren’t true, for instance, you have a larger or uneven load or can’t position the load correctly, then the load’s center of gravity is shifted, and capacity is diminished.

How to Calculate the Load Capacity

To correctly calculate if your forklift can safely handle a larger load, you need to calculate the load for a forklift accurately. To best illustrate this calculation, let’s say that you’re trying to move a pallet or other item that is eight feet long (96 inches), using the forklift with the same data plate shown in the first example. In that case, you’ll follow these steps:

- Calculate the actual load’s center of gravity by dividing its length in half. So, in this example, 96 inches / 2 = 48 inches.

- If that number is greater than the load center on the machine’s data plate, then divide the load center from the data plate by the actual load’s center. For example, 36 inches / 48 inches = 0.75.

- You’ll take that number and multiply it by the machine’s rated load capacity on the data plate. For example, 0.75 x 24,000 = 18,000 pounds.

- If the load you want to move that is 96 inches long weighs less than 18,000 pounds for the machine listed, then you can safely handle the load.

- If the load happens to weigh more than your calculation, then use a machine with a higher capacity or, if possible, decrease the weight of the cargo or lower its center of gravity.

The Load Moment

While you have your calculator out to determine the maximum load capacity of your forklift, you also want to be mindful of the load moment . The load moment is the product of the load’s weight by the load’s distance from the fulcrum or pivot point. In the case of a sit-down counterbalanced forklift, the fulcrum is the axel of the front wheels. This number is essential because it determines how much force is being applied that could cause the forklift to overturn.

To calculate the maximum load moment, let’s say we have a forklift with a 24-inch load center and a capacity of 3,000 pounds attempting to move an item that has a load center of 30 inches.

- Multiply the data’s plates load center and capacity. In this example, 24 inches x 3,000 pounds = 72,000 inch-pounds.

- Take the maximum load moment and divide it by the load’s center distance. So, 72,000 inch-pounds / 30-inches = 2,400 pounds.

- If the load weighs more than this number, then you cannot safely move it without the risk of tipping the forklift.

Dangers of Miscalculating Load Capacity

When attempting to use a new forklift, whether it’s your first time using it or the machine is brand new to your facility, you always want to be sure you’re calculating load capacity correctly. If you miscalculate, you could be subjected to the forklift tipping over, the load falling, or damage to the forklift. That’s why you must know how to calculate these numbers accurately.

Tips for Safely Handling Loads while Using a Forklift

Beyond an accurate calculation of lifting capacity and the maximum load moment, there are also some general safety tips for transporting larger loads.

- Use extra caution when handling loads at or near capacity

- With loads near-maximum capacity, travel with the mast tilted back to keep the load stable

- Ensure loads are centered because off-centered loads can cause tip-overs

- See if the load you’re transporting is damaged or loose, and fix it before attempting to move it

- Distribute the heaviest part of the load near the front wheels

Ready to Purchase a Used or New Forklift? Contact Sam’s Mechanical!

Whether you’re looking for new forklifts for sale or ones with a high capacity to move larger loads, Sam’s Mechanical has you covered! We have plenty of new and used material handling equipment, accessories, and related equipment, so you can find the perfect model to fit your needs. If you need to move a large load only once, you can even rent a forklift from us with enough capacity to move it.

No matter what your forklift or pallet racking needs are, Sam’s Mechanical is your one-stop forklift shop and can assist you!

- Skip to main content

- Skip to primary sidebar

- Skip to footer

Conger Industries Inc. - Wisconsin's Material Handling Experts

We help businesses move material at peak efficiency with the right equipment & solutions

Updated June 14, 2024

How to Transport a Forklift | Best Practices & Safety Tips

For many businesses, forklifts are essential equipment for lifting and moving heavy loads.

They can weigh anywhere between 3,000 to 20,000 pounds, making transporting a forklift from one worksite to another quite challenging.

Proper handling during transport prevents accidents and injuries while preserving the machine’s condition and minimizing repair costs.

Since forklifts are not classified as automobiles, they require specific transport methods for public road travel as we will learn in this detailed guide.

Let’s dive in!

Table of Contents

Understanding Forklift Transport

Forklift transport involves many ways to move forklifts from one location to another.

Forklift Transport Options

There are various options you can choose from when you need to transport forklifts, such as:

1. Tow Trailer

A tow trailer provides a fast and budget-friendly option for transporting forklifts. However, ensuring the trailer has sufficient weight capacity can withhold your lift. Once you have verified the trailer has enough weight capacity, drive the forklift onto the trailer and secure it firmly with straps or chains. This option is suitable for short to medium distances and is somewhat easy to arrange.

Also, before you set off, confirm that the lift is rigged and secured.

2. Tilt Tray Truck

At its core, a tilt tray truck excels in transporting forklifts, boasting the capacity to haul up to four forklifts, contingent upon their size and weight. These trucks feature a tilt tray bed, making them convenient for loading and unloading forklifts with ease.

3. Flatbed Truck

A flatbed truck provides adequate space and a substantial weight capacity to accommodate one or even multiple forklifts. They come equipped with a low deck, which ensures easy clearance when passing under bridges or through tunnels.

4. Automated Tailgate

An automated tailgate is not only the largest but also the safest way to transport forklifts. It enables the transportation of large quantities of forklifts due to its substantial weight capacity. Nevertheless, it is crucial to plan the route to avoid low bridges.

Before making a final decision about forklift transport, examine carefully these options. This consideration will enable you to identify appropriate transportation option. Plus, you can reduce the risk of delays when transporting these heavy machinery.

Warehouse managers often rely on forklifts as their trusted companions. Forklifts enable smooth and efficient movement of large and heavy objects within the distribution center or the warehouse. As powerful as they are, shipping them can be quite a headache.

Challenges of Shipping Forklifts

One of the primary challenges in shipping forklifts is the limited demand for specialized shipping services. This demand leads to an increase in the cost of transporting forklifts. Since flatbed carriers, which generally have higher rates, are predominantly used for shipping forklifts, the total expense can often surpass initial estimates.

As a result of the low demand for forklift shipping, carrier selection becomes a problem, as there are fewer dedicated carriers for this specific type of shipment.

For instance, the demand for auto shipping is very high. Due to this high demand, more vehicle carriers are available, which drives down prices and increases shipping availability. The lack of demand for forklift shipping leads to higher prices and lower availability.

Another challenge of shipping forklifts is loading and unloading them onto trucks or containers. Given their weight and dimensions, forklifts often need specialized equipment. Utilizing equipment such as ramps or cranes is essential for lifting and precise positioning of the vehicles.

Legal Axle Weight Limits

When shipping a forklift, consider factors such as legal axle weight limits. It is the maximum weight that a single axle or a group of axles on a vehicle can carry without exceeding the legal limit set by transportation authorities. These weight limits are in place to ensure the safety of the roads, bridges, and other infrastructure. They also help prevent excessive wear and tear on vehicles.

The shipping method is influenced by its size, forcing you to utilize specialized trailers such as dry vans.

The dry van boasts a weight capacity of approximately 45,000 lbs and can house freight up to roughly 9 feet, 2 inches in height. Should a forklift exceed this height limitation, there exist alternative transport methods. One can either detach the mast and forks of the forklift to fit within the van or opt for transportation on a flatbed trailer.

A standard flatbed height should be five feet high, allowing 8.5-9.5 feet of vertical space to transport a forklift with its forks in the downward position. In certain regions, this height may vary slightly.

When transporting taller forklifts, opting for a step-deck or a low-boy trailer is advisable as they offer increased vertical clearance.

However, depending on the height and regulatory requirements, you may need to obtain a permit for shipping taller forklifts.

Some heavy-duty forklifts, while adhering to legal weight restrictions, can exert a significantly higher pressure on the floors of trailers. This phenomenon largely stems from their design, which combines substantial mass with a compact footprint.

With such forklifts , the trailer floor must be sturdy enough to accommodate this weight without collapsing or sustaining damage.

Clearance Height Considerations

Throughout the entire route, awareness of the clearance height is essential. Clearance height refers to the available vertical space that allows the forklift , including its mast, to pass through without any obstacles.

Essentially, to ensure a smooth process while transporting forklifts, several clearance height considerations should be taken into account, including:

- Bridge and overpass clearances : Check the height restrictions of bridges, overpasses, and tunnels along the planned route. Make sure the forklift, including any raised attachments or masts, can clear these structures without causing any accidents or damage.

- Entrance and exit clearance : Determine the clearance height at entry and exit points, such as parking lots, warehouses, or other locations involved in the transportation route. Ensure that the forklift can navigate through these areas.

- Doorway and passage heights : Measure the height of doorways, narrow passages, or any other points the forklift needs to pass through. Compare these measurements with the height, including raised attachments, to confirm enough space exists.

- Loading and unloading areas : Consider the clearance height at loading docks, ramps, or any areas where the forklift will be loaded or unloaded. Verify that the height allows for a safe forklift transfer without any height constraints.

- Construction and road work : Be aware of ongoing construction or roadwork along the transportation route. Temporary structures or elevated platforms could affect the clearance height. Thus, stay updated on potential changes that might impact the passage.

Safety Precautions and Procedures

By prioritizing safety, you can identify potential hazards and decrease the risk of accidents or damage. Moving a forklift does not have to be overly complicated— all it requires is a careful approach and compliance with proper safety precautions.

Safety Precautions for Forklift Transport

Consider the following safety precautions when moving forklifts:

1. Weigh Your Forklift

Before transporting your forklift, determine its weight and ensure it is compatible with your trailer. Check the weight capacity of your trailer, as capacities can vary depending on the specifications.

Though it is not just about weight, consider the length of your forklift trailer to ascertain whether it can accommodate your specific forklift.

2. Inspect Your Forklift

Ensure your forklift is working before loading it onto the transport vehicle. Inspect the forklift and confirm that everything is in order. Remember to place wheel chocks to prevent any accidental rolling of the forklift.

If the trailer is not attached to a truck, employ a nose jack and position it beneath the front of the trailer. This action ensures stability and safeguards against any potential tipping or imbalance during the forklift loading process onto the trailer.

3. Center Your Forklift

Transporting a forklift in a trailer demands mindful attention to centering the machine properly. Start by lowering the forks onto the floor and tilting them forward. Place wooden blocks behind every wheel of the forklift to offer stability. Secure the blocks by driving screws into the wooden floor and the blocks of the transport vehicle.

4. Load Your Forklift

When loading your forklift onto the truck or trailer, drive it in reverse, ensuring the forks are facing away from the transport vehicle. This positioning helps to guarantee safer and more efficient loading and unloading. Be aware of the specific forklift transport policies recommended for your job site, as they may have additional requirements or guidelines to follow.

5. Switch off the Fuel Supply

Before departing, ensure to disconnect the propane tank. For those operating diesel- or gasoline-powered forklifts, verify that the fuel tank is tightly fastened to avoid potential fuel spills. Additionally, disconnecting the battery terminal is advisable to prevent electrical arcing. Ensuring the battery of an electric forklift is fully charged before setting off is crucial.

6. Utilize Chains and Come-Alongs

Chains and come-alongs help in fastening the forklift. Tighten them to the edges of the truck bed and ensure they are firmly secured. Create four anchor points at every corner of the truck, utilizing at least two chains or come-along for each anchor point.

Securing a Forklift for Travel

When using a dry van, firmly secure your forklift using the blocks and braces nailed to the trailer. It is worth noting that some dry van carriers may decline to transport forklifts due to the holes and nails left behind by this bracing.

Utilize straps and chains as an additional safeguard against any movement during transit. Utilizing padding beneath these constraints is recommended, as it acts as a safeguard, mitigating the risk of damage caused by friction on the forklift.

The process of loading a forklift onto a trailer generally presents minimal difficulty. In many instances, forklifts, like other self-propelled vehicles, can be maneuvered onto trailers using ramps or docking platforms.

Following placement on the vehicle, ensuring proper securement is critical—a task typically undertaken by specially trained personnel adept in brace-and-block techniques. In certain situations, drivers may assume responsibility for securing their load thoroughly—conducting inspections post-securement—to mitigate risks associated with property damage or injuries during transport.

Securing Forklift with Ratchets and Chains

Using ratchet and chains often results in a slower but more stable loading and unloading process. Their handles store less energy, making them safer to use as the risk of recoil is minimal.

Here is a step-by-step guide on how to secure a forklift with ratchets and chains:

- A) Position the forklift : Drive your forklift onto the flatbed truck, carefully positioning it in the desired location for transport.

- B) Identify anchor points : Locate suitable anchor points to attach the ratchets and chains. These anchor points should be capable of withstanding the weight and force exerted by the forklift during transportation.

- C) Attach the chains : Tighten the chains and ensure they are attached to a strong and stable point on the forklift frame. Avoid attaching chains to any moving parts or delicate components.

- D) Connect the ratchets : Attach ratchets securely to the chains and ensure they are fastened to the anchor points on the truck. The ratchets must be correctly attached to maintain a firm grip on the forklift.

- E) Check stability : Once the chains and ratchets are in place, assess the forklift’s stability. Look for any signs of movement or shifting. If necessary, adjust the tension of the chains and ratchets to achieve a firm and stable position.

- F) Conduct a safety inspection : Inspect the securements, including the chains, ratchets, and anchor points, to ensure everything is in place. Verify that all connections are tight and there are no indications of potential loosening or failure.

Safety Procedures During Transport

As discussed earlier, transporting forklifts requires keen attention to safety to protect both personnel and the transported equipment.

Adhering to safety procedures significantly reduces the risk of potential hazards.

First, tighten the forklift to the transport vehicle using chains, straps, or ratchets to prevent movement or shifting during shipping.

Maintain proper weight distribution on the transport vehicle to promote stability. Evenly distribute the weight of the forklift to minimize imbalances that could contribute to accidents or loss of control.

Comply with the regulations and guidelines specific to forklift transport. Compliance helps guarantee a safe and legal transport process.

Before transportation, conduct a thorough inspection of the forklift. Look out for any signs of leaks, components that may have become loose, or any mechanical irregularities. It is essential to verify that all critical systems—such as brakes , steering mechanisms, and lighting —are working.

If the forklift has detachable parts, secure or remove them before transportation. Loose or unsecured parts can cause accidents or fatalities during transit.

Choosing the Right Carrier and Equipment

When you are selecting a suitable carrier to ship your forklift, here is what you will need to check before settling on a carrier for your forklift shipment:

- Experience : Choose a carrier with experience in transporting heavy machinery and a track record of handling similar shipments, particularly forklifts.

- Equipment and resources : Check if the carrier has the right equipment and resources for forklift transportation They should have specialized trailers or flatbed trucks designed for hauling heavy machinery. Also, consider if they have the necessary loading and unloading equipment, such as ramps or cranes, to handle the forklift safely.

- Licensing and insurance : Verify that the carrier holds licenses and permits for transporting heavy machinery like forklifts. Find out if they have sufficient insurance coverage to protect your forklift in case of any damage or loss during transportation.

- Safety record : Look for carriers with a good safety track record and positive customer feedback. This information gives you confidence that they can handle your forklift shipment safely.

- Transit time and delivery optio ns: Confirm the estimated transit time and the available delivery options. You may require expedited shipping or specific delivery arrangements. Discuss these requirements with the carrier to ensure they can meet your timeline and preferences.

- Cost and pricing : Obtain quotes from multiple carriers and compare pricing structures. Evaluate their value, accounting for factors such as reputation, equipment quality, and level of service.

Specialized Equipment

Specialized equipment and trailers depend on the nature of your forklift transportation needs. The following are the various types of specialized equipment you can use in forklift transport:

- Cranes and lifts : Cranes or lifts may be used to load or unload forklifts onto trailers and transport vehicles. These heavy-duty lifting devices can handle the weight and size of forklifts and are commonly employed when dealing with exceptionally heavy or oversized forklifts.

- Ramps and dock plates : This specialized equipment bridges the gap between the ground and the trailer or transport vehicle. They provide a smooth transition for forklifts moving from the ground onto the transport equipment.

- Straps and chains : Straps and chains tightly fasten the forklift to the trailer or transport vehicle, preventing movement during transportation.

In forklift transport, specialized trailers accommodate the unique dimensions and weight of forklifts, simplifying the loading and unloading process.

Specialized Trailers for Forklift Transport

These specialized trailers provide the necessary features and configurations to transport forklifts, minimizing the risk of damage.

1. Drop Deck Trailers

Also referred to as step deck trailers, drop deck trailers have a lower deck height at the front and a higher deck at the rear. This design allows forklift transportation without height restrictions, especially for taller forklift models.

2. Side Loader Trailers

Side loader trailers are specifically designed with a side-loading mechanism. These trailers enable forklifts to be loaded and unloaded from the side, enhancing convenience and safety during the transportation process.

3. Lowboy Trailer

Lowboy trailer has a low deck height, allowing forklifts to be loaded and transported with minimal ground clearance. They are useful when transporting larger or taller forklifts that may not fit on standard trailers.

Forklift Shipping Methods

The first step of loading a forklift onto a trailer is to check the weight of the forklift. Knowing the weight of the forklift enables you to choose the suitable securement method and select the proper straps needed to fasten the forklift effectively.

As soon as you have reviewed the weights, you will need to center the trailer so that both sides have equal distances from the trailer edge. After that, tilt the forks forward. Fix sturdy screws behind each wheel of the forklift to ensure that it stays immobile and stable.

Next, turn off the engine, cut off the fuel supply of the forklift, and disconnect the batteries. To ensure proper security, utilize chains and straps to fasten the forklift.

While shipping this heavy machinery, you will need reliable and specialized freight shipping companies that can handle the task efficiently. These companies have the expertise and resources to handle the unique requirements of forklift transport.

- FedEx Freight

- UPS Freight

- XPO Logistics

- Old Dominion Freight Line

If you need to relocate a forklift, it is essential to familiarize yourself with the available options for loading, shipping, and delivering.

The choice of forklift transportation hinges on your specific needs, the size of the forklift, and the availability of suitable transportation. To discover the best practices for successfully shipping your forklift, continue reading!

Know What Your Forklift Weighs

Forklifts come in various weights. While some forklifts may have a relatively modest weight of around 9,000 pounds, which still surpasses the weight of an average vehicle, there are also larger forklifts that can tip the scales at over 100,000 pounds.

The weight of your forklift determines the transportation method. For instance, certain roads impose restrictions to specific weight limits. To ensure compliance with these restrictions, you must carefully assess the combined weight of your trailer and forklift. Understanding the vehicle’s weight and the trailer’s mass is essential, alongside an awareness of the load restrictions prescribed by the roads you plan to navigate.

Be Aware of Your Forklift Dimensions